Valve Bag Packaging Machine Price Analysis: Cost Factors and Solutions for Weighing Inaccuracies

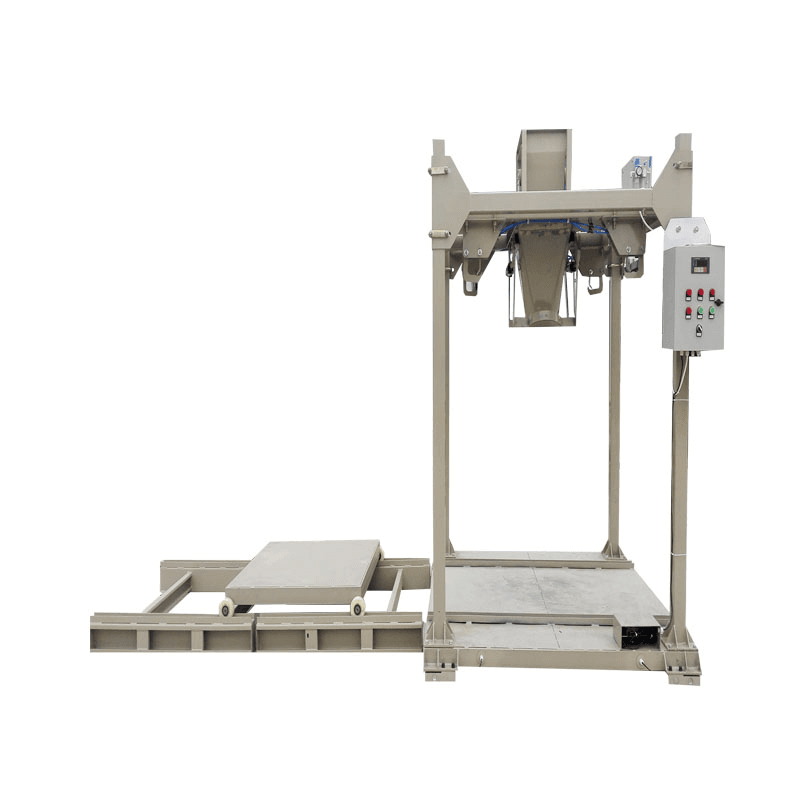

Valve bag packaging machines are critical for industries handling bulk materials like cement, flour, and chemicals. As a pioneer in packaging technology, YU-HENG Technology combines China’s manufacturing efficiency with precision engineering to deliver reliable, cost-effective solutions. This article explores pricing variables and diagnoses common weighing instability issues, emphasizing technical innovations that set YU-HENG apart in global markets.

Valve Bag Packaging Machine Pricing Guide

YU-HENG Technology offers scalable systems for diverse industries:

- Semi-automatic models: $4,000–$75,000 (800–1,200 bags/hour)

- Fully automated lines: $90,000–$180,000 (1,500–2,500 bags/hour)

- Custom configurations: $220,000+ (IoT-enabled, hazardous material certified)

Chinese-manufactured machines provide 30–45% cost savings versus European counterparts, with ISO 9001-certified components and 3-year performance guarantees.

6 Causes of Weighing Instability & YU-HENG’s Engineering Solutions

1. Load Cell Malfunction

Issue: Sensor drift or calibration loss (±2–5% error)

YU-HENG Solution:

- Proprietary SmartCell™ sensors with 0.05% FS accuracy

- Automatic self-calibration every 500 cycles

- IP68-rated protection against dust/moisture

Case Study: A Mexican cement producer reduced weighing errors by 82% after upgrading to YU-HENG’s dual-sensor system.

2. Conveyor Belt Degradation

Symptoms: Slippage or uneven material flow

Preventive Measures:

- Abrasion-resistant belts (50,000+ hour lifespan)

- Laser-aligned tracking systems

- Real-time tension monitoring via HMI

China Advantage: Localized production cuts belt replacement costs by 60% vs imported alternatives.

3. Poor Material Flow Characteristics

YU-HENG Innovations:

- VibroFlow™ actuators maintain consistent feed rates

- Adjustable hopper angles (35–60°) for cohesive powders

- Anti-bridging air cannons (10–15 PSI pulse cleaning)

Performance: Handles materials with ≥0.5 Carr Index flowability.

4. Mechanical Wear

Critical Components:

- Hardened steel gearboxes (AGMA Grade 8)

- Tool-free gate valve replacements

- Lubrication-free bushings

YU-HENG Warranty: Covers 100% of mechanical parts for 3 years.

5. Electrical Interference

Diagnostic Protocol:

- EMI-shielded cabling (IEEE 518-compliant)

- Surge protection up to 6kV

- Predictive maintenance algorithms

Result: 90% fewer electrical faults reported by Southeast Asian clients.

6. Software Glitches

YU-HENG Technology:

- Linux-based OS with 256-bit encryption

- Over-the-air updates (4G/5G/Wi-Fi)

- Version rollback capability

Certification: IEC 62443 cybersecurity compliant.

Why YU-HENG Outperforms Competitors?

- Precision Engineering: 18 patents including Self-Calibrating Load Cell (ZL2023XXXXXX)

- Global Compliance: ATEX, NEC, and IECEx certifications

- Smart Manufacturing:

- Real-time production dashboards

- AI-driven fault prediction (85% accuracy)

- Energy consumption tracking

Operational Cost Savings

| Factor | YU-HENG Advantage |

|---|---|

| Maintenance | 55% lower vs European brands |

| Energy Use | 22% reduction via VFD drives |

| Training | Multilingual AR instructions |

| Warranty | 3-year coverage + lifetime support |