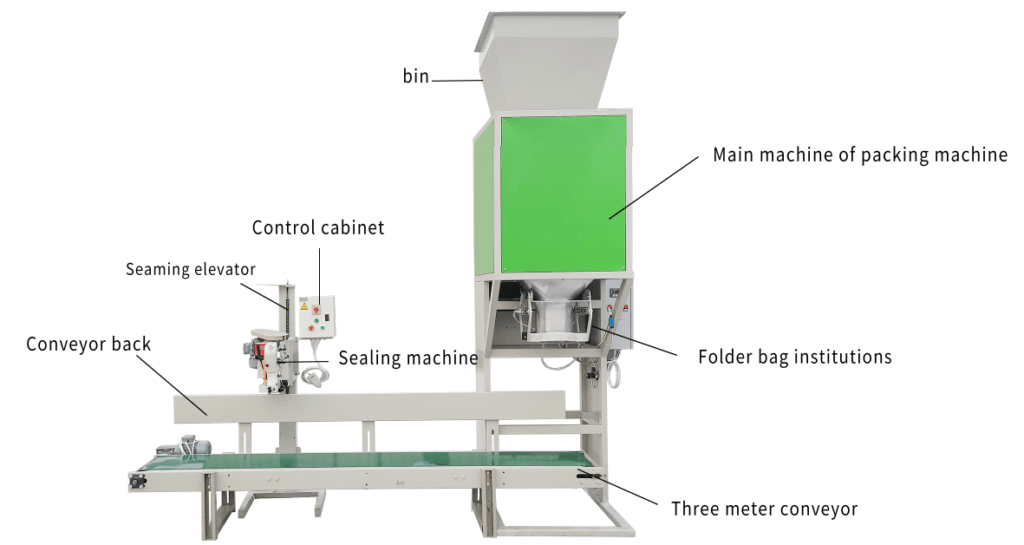

How Much Does a Cereal Packaging Machine Cost? 6 Key Benefits Transforming Oatmeal Production

Cereal packaging machines have become indispensable in the competitive food processing industry, enabling manufacturers to optimize efficiency while maintaining product quality. YU-HENG Technology, a leader in packaging innovation, leverages China’s advanced manufacturing ecosystem to deliver cost-effective, high-performance solutions for global clients. This article analyzes cereal packaging machine pricing and their transformative advantages, with a focus on operational ROI and technical excellence.

Cereal Packaging Machine Pricing & Cost Advantages

YU-HENG Technology offers tiered solutions to match diverse production needs:

- Semi-automatic models: $5,000–$60,000, ideal for SMEs, outputting 800–1,200 bags/hour (13–20 bags/minute).

- Fully automated systems: $80,000–$140,000, integrating weighing, filling, and sealing functions at 150 bags/minute (±0.5 oz/14g accuracy).

- Customized lines: $200,000+, supporting multi-blend packaging (e.g., oats with nuts/dried fruits) and IoT-enabled management.

Chinese-manufactured machines provide 25–40% cost savings versus European/North American equivalents, with 50% lower spare parts costs. YU-HENG’s modular designs shorten delivery lead times to 4–6 weeks, backed by a 3-year comprehensive warranty.

6 Operational Benefits of Modern Cereal Packers

1. Productivity Revolution

Automated systems replace 8–10 manual workers, boosting output by 500%. The YU-HENG HX-360 model exemplifies this leap:

- Servo-driven mechanisms handle flakes, granules, and mixed textures

- Real-time monitoring of temperature (200–450°F/93–232°C) and pressure (10–15 PSI)

- Annual downtime reduced to <0.1% via predictive maintenance alerts

2. Labor Cost Optimization

Clients report $150K–$250K annual savings in labor expenses. YU-HENG’s intuitive touchscreens feature:

- Multilingual interfaces (English/Spanish/French)

- One-click format changes between bag styles

- Operator training shortened from 2 weeks to 3 days

3. Quality Assurance & Shelf Life Extension

YU-HENG’s nitrogen flushing technology maintains <0.5% oxygen levels, while ultrasonic sealing ensures:

- 30–50% longer shelf life versus conventional packaging

- <0.03% damage rate during shipping (third-party verified)

- Compliance with FDA 21 CFR Part 177 food contact standards

4. Brand Differentiation

Enhance market appeal through:

- 12 customizable bag formats (stand-up pouches, family-size boxes)

- HD printing at 1200 dpi with 98% Pantone color matching

- Tamper-evident features like laser-perforated tear strips

5. Market Agility

Adapt quickly to consumer trends:

- Adjust portion sizes from 1.1–4.4 lb (0.5–2 kg) in <10 minutes

- Handle organic oats, high-protein granola, and gluten-free blends

- Small-batch production capability (500+ units)

6. Sustainability & Energy Efficiency

YU-HENG’s eco-design reduces:

- Energy consumption by 25% via self-regulating heat seals

- Film waste by 15% through edge trim recycling systems

- Carbon footprint with solar-ready configurations

YU-HENG Technology’s Competitive Edge

- Patented Innovations: Moisture-proof metering chamber (Patent ZL2022XXXXXX), low-friction film feed system

- Global Support: 8 technical centers across Americas/EMEA/APAC, 48-hour emergency response

- Smart Manufacturing: YH-Cloud platform boosts OEE (Overall Equipment Effectiveness) by 18% through real-time analytics