What Is the Price of Powder Packaging Machinery? Quick Solutions to Common Operational Issues

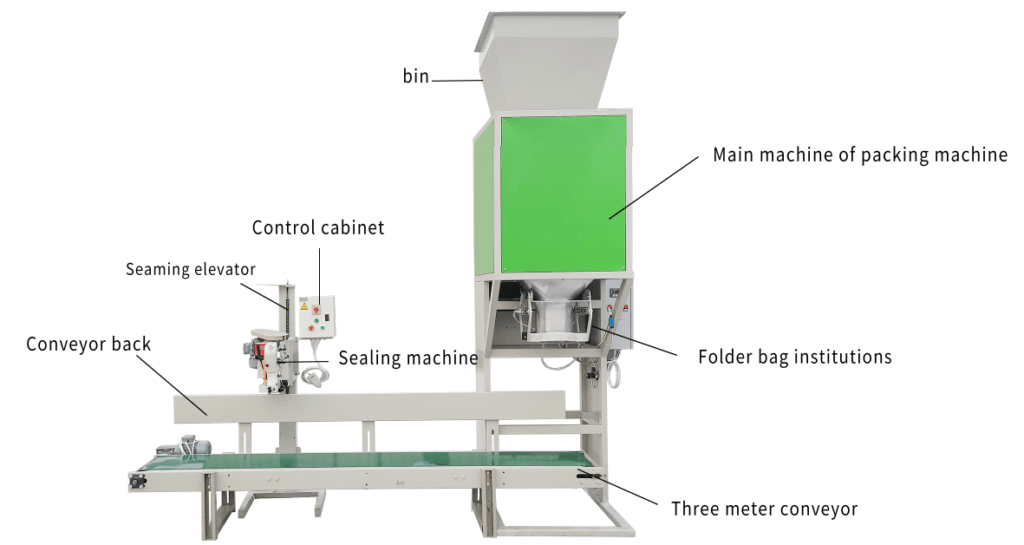

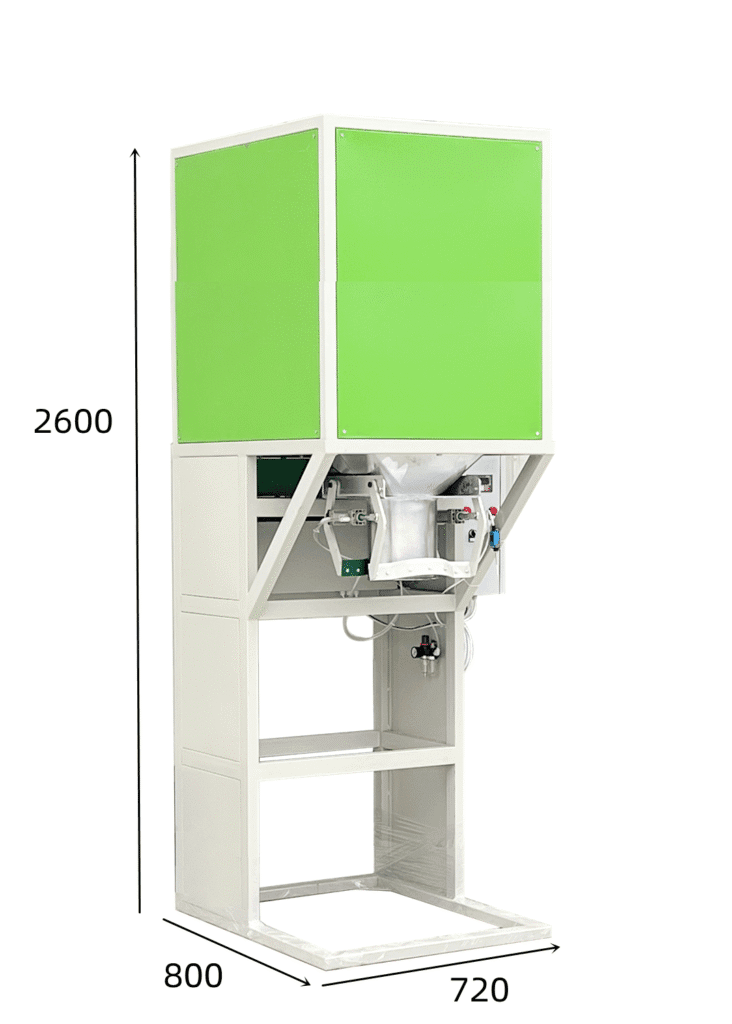

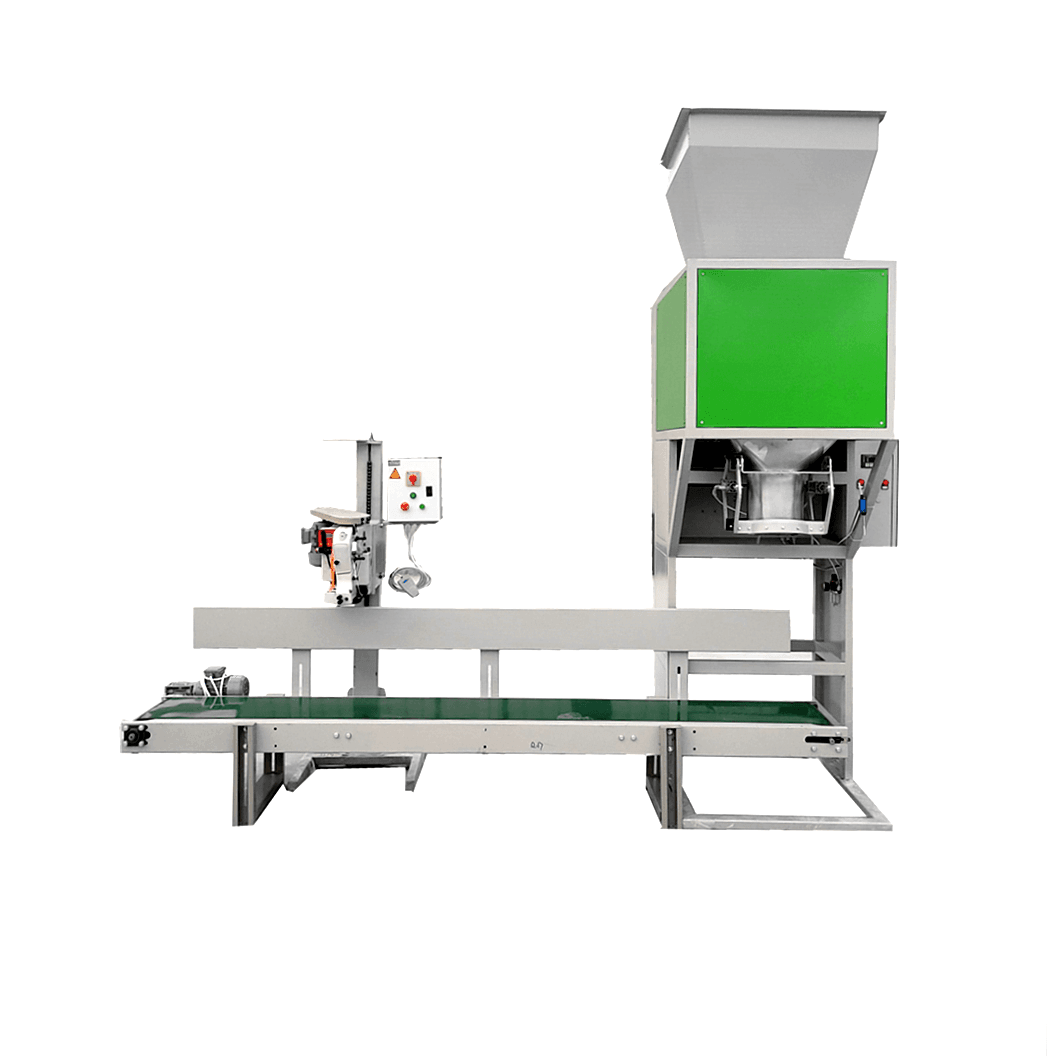

Powder packaging machinery plays a critical role in industries ranging from food production to pharmaceuticals, offering precision and efficiency for fine material handling. As a leader in this field, YU-HENG Technology combines China’s cost-effective manufacturing expertise with globally compliant engineering to deliver reliable solutions. Below, we address pricing considerations and practical troubleshooting strategies while highlighting the advantages of Chinese innovation and YU-HENG’s technical prowess.

Powder Packaging Machinery Pricing Overview

YU-HENG Technology provides tiered solutions to meet diverse production needs:

- Semi-automatic models: Starting from approximately $3,000

- Mid-range automated systems: $60,000–$130,000

- High-speed GMP-compliant lines: $180,000+

Chinese-manufactured equipment typically offers 30–40% cost savings compared to European or North American alternatives, with no compromise on ISO 9001-certified quality.

5 Common Operational Issues & Rapid Resolution Strategies

1. Material Clogging

Symptoms: Irregular flow, machine jams, or complete stoppage

YU-HENG Solutions:

- Patented Anti-Bridging Design: Reduces clogs in hoppers and augers

- Quick-Clean Access Panels: Enable debris removal in <10 minutes

- Compressed Air Ports: Integrated blast cleaning for stubborn residues

China’s Advantage: Durable 316L stainless steel construction resists material adhesion, extending service intervals by 50%.

2. Conveyance System Failures

Common Issues: Belt slippage, chain misalignment, or motor stalling

Troubleshooting Steps:

- Inspect tension on 1–2″ (25–50 mm) wide conveyor belts

- Lubricate roller bearings every 300 operating hours

- Replace worn sprockets using YU-HENG’s tool-free modular components

YU-HENG Innovation: SmartLoad™ sensors auto-adjust feed rates, preventing overloads that cause 80% of conveyor issues.

3. Dosing Inaccuracies

Root Causes: Humidity fluctuations, powder compaction, or sensor drift

Precision Recovery:

- Recalibrate auger fillers using test weights (5–50 lb / 2.3–22.7 kg)

- Activate vibration-assisted flow aids for cohesive powders

- Utilize YU-HENG’s CloudCal™ software for real-time adjustment logging

Performance Benchmark: Maintains ±0.35 oz (10 g) accuracy even with challenging materials like titanium dioxide or talc.

4. Weak Seal Integrity

Warning Signs: Leaks during transport, package inflation, or spoilage

Optimization Methods:

- Adjust heat jaws between 300–450°F (149–232°C) based on film thickness

- Test seal strength at 2–5 PSI (14–34 kPa) air pressure

- Replace worn Teflon® strips every 6–8 months

YU-HENG Advantage: Dual-seal technology with laser-aligned jaws ensures 99.9% leak-free performance, validated by third-party labs.

5. Mechanical Breakdowns

Typical Faults: Electrical shorts, gearbox noise, or PLC errors

Rapid Response Protocol:

- Reset main circuit breakers (200–480V compatible)

- Check lubrication levels in reduction gearboxes

- Review error codes via 10″ HMI touchscreen

- Contact YU-HENG’s 24/7 global support team

Preventive Maintenance:

- Annual motor inspections (5–15 HP / 3.7–11 kW models)

- Quarterly greasing of cam followers and linear guides

- Monthly air filter replacements in dusty environments

Why Choose YU-HENG Technology?

- Cost Efficiency: Localized production cuts lead times by 6–8 weeks

- Smart Diagnostics: IoT-enabled machines predict 70% of faults before failure

- Hygienic Design: CIP-ready systems meet FDA 21 CFR Part 11 standards

- Global Support: 18-month warranty with on-site training in 50+ countries