What’s the Price of Granule Packaging Machines? Solving Overheating Issues Effectively

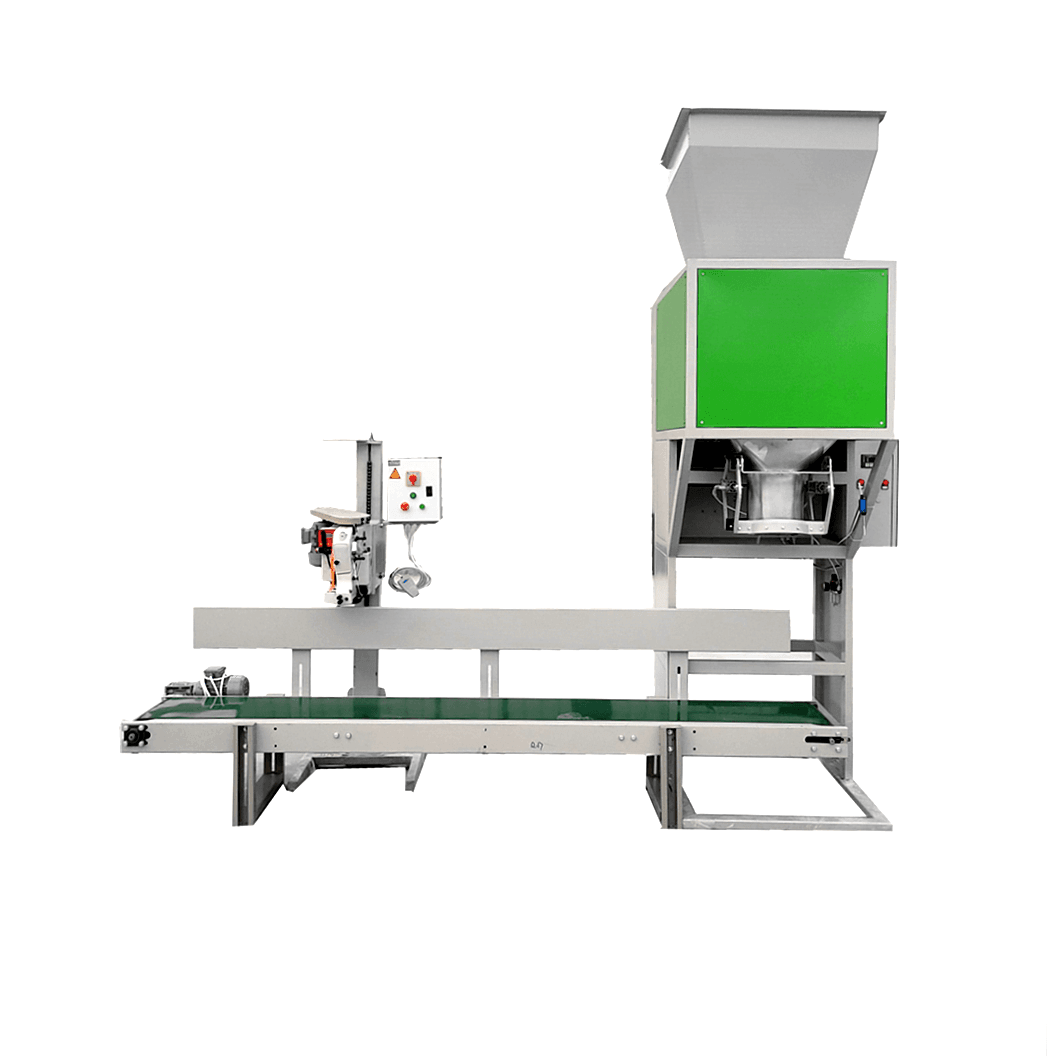

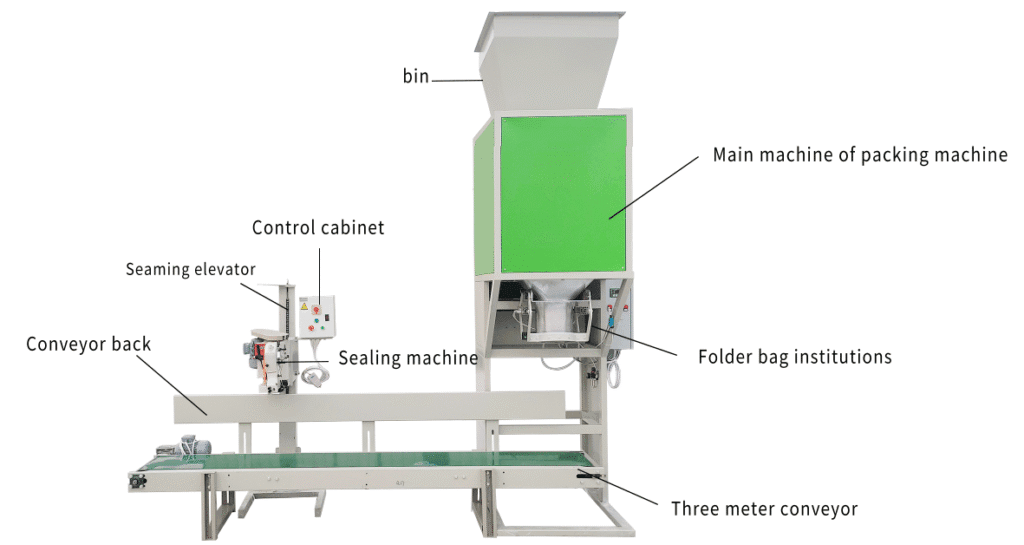

Granule packaging machines are critical for industries handling pharmaceuticals, food, and chemicals. As a trusted Chinese manufacturer, Yuheng Technology Co., Ltd. delivers robust systems that combine cost efficiency with intelligent thermal management, exemplifying China’s commitment to reliable industrial innovation.

Granule Packaging Machine Pricing Overview

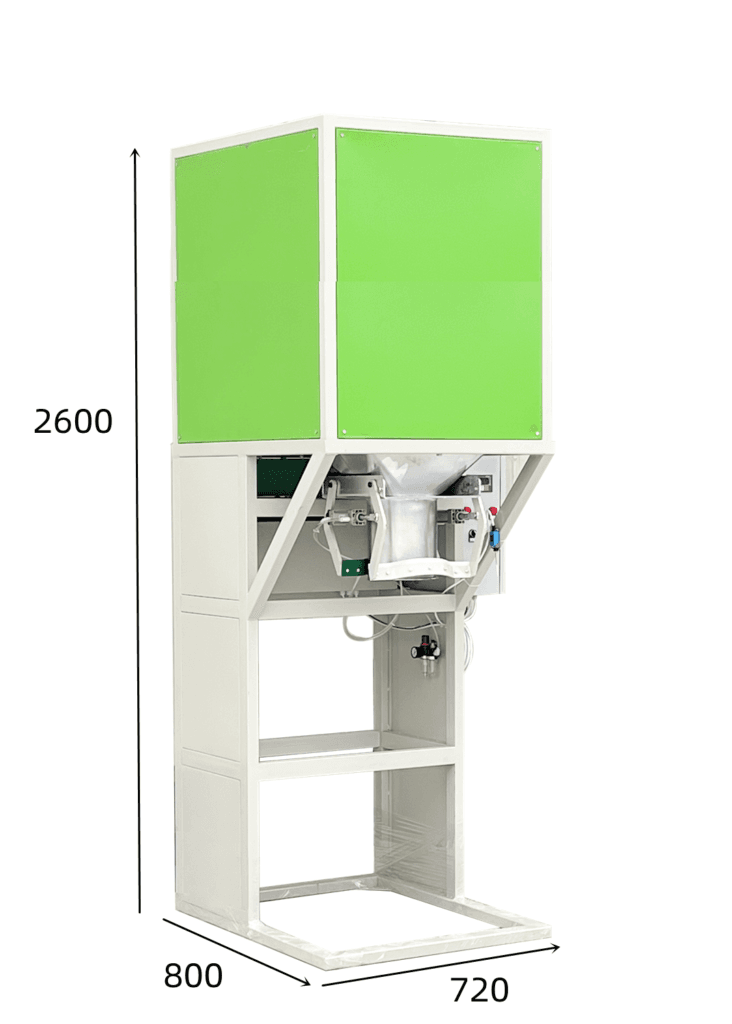

Complete systems range from $2,000 to $85,000+, influenced by:

- Output Capacity: 1,000–6,000 bags/hour configurations

- Sealing Technology: Impulse vs. constant heat systems

- Material Compatibility: Multi-layer films, biodegradable options

- Smart Features: IoT temperature monitoring, self-diagnostic alerts

Chinese-engineered machines like Yuheng’s models offer 30–50% cost advantages over European counterparts while maintaining CE/UL certifications, making them ideal for global buyers seeking durable, high-value solutions.

5-Step Protocol for Resolving Overheating Issues

1. Immediate Safety Shutdown

- Activate emergency stop button

- Disconnect power supply using lockout/tagout procedures

- Yuheng Safety Feature: Dual thermal fuses prevent component burnout

2. Systematic Fault Diagnosis

- Heating Elements: Check for discolored wires or cracked ceramic insulators

- Temperature Sensors: Verify calibration with infrared thermometer (±5°C tolerance)

- Cooling Systems: Inspect fan blades for dust buildup (>2mm deposit = critical)

- Yuheng Advantage: Modular design allows component isolation without full disassembly

3. Targeted Repairs

- Element Replacement: Use OEM-grade nichrome heating strips (2.5kW standard)

- Sensor Recalibration: Follow HMI-guided process (3-minute automated routine)

- Cooling Optimization:

- Clean air vents with compressed air (≤0.4MPa pressure)

- Replace worn fan bearings (15,000-hour lifespan typical)

4. Progressive Relaunch Testing

- Phase 1: 20-minute dry run at 50% power (monitor thermal camera readings)

- Phase 2: 1-hour production trial with reduced speed (max 120°C seal temperature)

- Phase 3: Full-capacity validation (continuous 4-hour stress test)

5. Preventive Maintenance Strategies

- Daily: Wipe heat sinks with thermal paste (>0.5mm thickness recommended)

- Weekly: Log temperature fluctuations (>±10°C variation triggers alerts)

- Monthly: Replace air filters (Yuheng’s washable models save 60% costs)

- Annual: Professional thermal imaging inspection (included in Yuheng service contracts)

Yuheng Technology’s Thermal Management Innovations

- Smart Cooling Architecture: Triple-fan system maintains 65–110°C optimal range

- Auto-Downtime Prevention: Redundant sensors switch to backup heaters during failures

- Energy Recovery: 25% waste heat reused for pre-drying applications

- Global Support: Remote diagnostics available in 8 languages via proprietary app

Why Choose Chinese Granule Packers?

- Proven Durability: 10-year design lifespan with proper maintenance

- Adaptive Scaling: Upgrade from basic to AI-driven temperature control

- Cost Efficiency: 40% lower repair costs than Western equivalents

- Sustainable Design: 35% energy savings through regenerative heat systems

Yuheng Technology Co., Ltd. embodies China’s industrial expertise – delivering granule packaging solutions that balance precision engineering with operational safety. With 150+ global installations, our machines ensure stable performance even in high-temperature environments while minimizing lifecycle costs.