Small Powder Packaging Machine Price Guide and Expert Disassembly Techniques

Introduction to Small Powder Packaging Solutions

In today’s industrial packaging environment, small powder packaging machines have become indispensable equipment for pharmaceutical manufacturers, food processing plants, and chemical production facilities that handle fine powdered materials. These specialized packaging systems are designed to provide precise dosing and efficient packaging of small quantities of powdered products, ensuring both accuracy and productivity. As an established Chinese manufacturer with over a decade of industry experience, Yuheng Technology Co., Ltd has emerged as a trusted global provider of high-quality small powder packaging solutions that combine precision engineering with the competitive advantages of Chinese manufacturing. Our machines are built to meet international standards while offering exceptional value through efficient production processes and reliable performance.

Comprehensive Price Analysis for Small Powder Packaging Machines

Understanding the investment required for small powder packaging equipment is essential for making informed purchasing decisions. The price range varies significantly based on automation level, production capacity, and specialized features. Entry-level semi-automatic models represent the most economical choice for small to medium operations, typically priced between $12,000 and $35,000. These systems offer basic packaging functionality with production capacities of 15-30 bags per minute, making them ideal for businesses establishing their first automated packaging lines or those with moderate production needs. While requiring more operator involvement than fully automated systems, they provide an excellent balance between functionality and affordability.

For growing businesses with higher production demands, mid-range automatic small powder packaging systems offer enhanced capabilities at price points ranging from $35,000 to $90,000. This category features more advanced technology including intuitive touchscreen control panels, improved weighing accuracy (±0.8%), and basic dust control mechanisms. With production capacities between 30 and 70 bags per minute, these machines are particularly well-suited for operations that require consistent output while maintaining flexibility for different powder types and packaging formats. The increased automation in these models significantly reduces labor requirements while improving overall packaging consistency and accuracy.

At the premium end of the spectrum, high-speed automated small powder packaging lines represent the most advanced solutions available, with prices ranging from $90,000 to over $200,000 depending on configuration. These sophisticated systems incorporate cutting-edge features such as full automation, pharmaceutical-grade precision (±0.3%), and advanced cleaning systems. Capable of processing 70 to 120+ bags per minute, they are designed for large-scale industrial operations where maximum throughput and precision are critical. Yuheng Technology takes particular pride in our ability to deliver these high-end systems with the reliability and performance expected by global customers, while maintaining the cost advantages of our Chinese manufacturing base.

Professional Disassembly Techniques for Small Powder Packaging Machines

Thorough Preparation Process

Proper preparation is the foundation for successful disassembly of small powder packaging machines. Begin by thoroughly reviewing the machine’s schematics and operation manual to understand its construction and key components. Gather all necessary tools including an assortment of wrenches, screwdrivers, pliers, and containers for organizing small parts. Prepare a clean, well-lit workspace with adequate space to lay out components as they are removed. Ensure the machine is completely powered off and disconnected from all power sources before beginning any disassembly work. Wear appropriate personal protective equipment including safety gloves, goggles, and a dust mask to protect against residual powder particles. Yuheng Technology includes detailed disassembly guides with each machine to assist customers with maintenance procedures, reflecting our commitment to user-friendly design and long-term equipment serviceability.

Systematic Labeling and Documentation Methods

Maintaining clear documentation throughout the disassembly process is crucial for efficient reassembly. Before removing any components, take comprehensive photographs of the machine from multiple angles to serve as a visual reference. Use numbered tags or colored stickers to label all cables, hoses, and electrical connections, noting their original positions. Create a detailed disassembly map or diagram that records the sequence of removal and the relationship between components. Pay special attention to marking alignment points and orientation of parts that have specific positioning requirements. Keep a notebook to record observations about component conditions, unusual wear patterns, or any difficulties encountered during disassembly. Yuheng machines feature color-coded connections and standardized component markings to simplify this process, demonstrating our focus on maintenance-friendly design.

Structured Disassembly Sequence

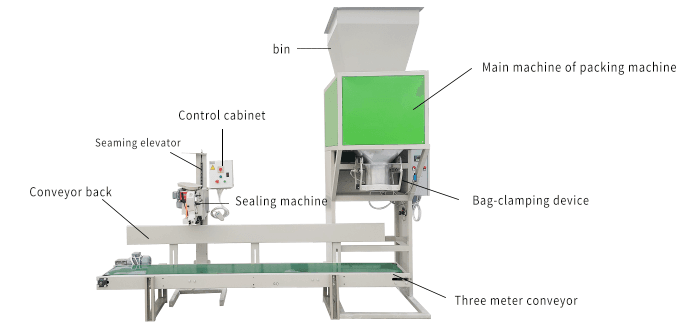

Following a logical disassembly sequence helps prevent damage and ensures efficiency. Start by removing all external covers, safety guards, and access panels to expose the internal components. Next, carefully detach control panels and electrical connections, taking care to properly label each wire and connector. Proceed to disconnect the powder feeding mechanisms, including hoppers, augers, or vibratory feeders. Remove the dosing and weighing components, which are typically the most precision-critical elements of small powder packaging machines. Separate the conveyor and bagging elements, taking note of their adjustment settings. Finally, access the internal drive systems and transmission components. Throughout this process, organize removed parts in the order of disassembly to facilitate reverse-order reassembly. Yuheng Technology designs its small powder packaging machines with modular components that simplify this disassembly process, reducing downtime during maintenance.

Essential Safety Considerations

Safety must remain the top priority throughout the disassembly process. Always work in a clean, well-ventilated area with adequate lighting to ensure good visibility of small components and fasteners. Use proper lifting techniques when handling heavy parts, and consider using mechanical assistance for particularly large components. Exercise caution when handling sharp edges or moving parts that may have tension or spring-loaded mechanisms. Never force components that seem stuck – instead, investigate the cause of resistance to avoid damage. Keep the work area organized and free of clutter to prevent tripping hazards or accidental damage to delicate parts. Yuheng Technology incorporates numerous safety features in our small powder packaging machines, including quick-release mechanisms and guarded access points, to make disassembly and maintenance safer for operators.

Effective Component Organization System

Implementing an efficient organization system for disassembled parts prevents confusion during reassembly. Use divided containers or compartmentalized trays to keep small fasteners and components organized by type and location in the machine. Group related components together in clearly marked storage bins or bags. Maintain separate areas for clean components awaiting inspection and parts that require cleaning or repair. Protect delicate components such as sensors or precision measuring devices with appropriate padding or dedicated containers. Create a numbered inventory list that corresponds to your disassembly sequence and labeling system. Yuheng Technology provides customized maintenance kits with our small powder packaging machines that include organization trays and component labels, demonstrating our attention to after-sales service and customer support.

Comprehensive Cleaning and Inspection Procedures

Once disassembly is complete, thorough cleaning and inspection ensures optimal machine performance upon reassembly. Clean all components using methods appropriate for their material and function – compressed air for removing powder residues, mild solvents for degreasing, and specialized cleaners for electrical components. Inspect each part for signs of wear, corrosion, or damage, paying particular attention to moving parts and sealing surfaces. Check all seals and gaskets for deterioration and replace as necessary. Verify the condition of bearings, bushings, and other wear-prone components. Measure critical dimensions on precision components to ensure they remain within tolerance specifications. Identify any parts that require replacement and document these needs for your maintenance records. Yuheng Technology offers comprehensive spare parts support for our small powder packaging machines, with worldwide shipping to minimize downtime during maintenance procedures.

Yuheng Technology’s Maintenance Advantages

With years of experience in small powder packaging solutions, Yuheng Technology has designed our machines with maintenance and serviceability in mind:

✔ Detailed, illustrated disassembly and assembly guides

✔ Color-coded and standardized component labeling

✔ Modular design for easier access and service

✔ Global technical support network

✔ Affordable genuine replacement parts

✔ Online maintenance training resources

✔ Preventive maintenance scheduling tools

Proper Reassembly Guidelines

When reassembling your small powder packaging machine, follow these best practices:

- Work in the exact reverse order of disassembly

- Frequently reference your documentation and photos

- Replace all worn or damaged components with genuine parts

- Apply proper lubricants to specified points

- Verify all electrical and mechanical connections

- Check alignments and adjustments

- Test operation gradually and systematically

- Complete final calibration and verification

Conclusion and Next Steps

Understanding small powder packaging machine costs and proper disassembly techniques helps maintain your equipment’s performance and longevity. Yuheng Technology combines Chinese manufacturing efficiency with international quality standards to deliver:

✔ Reliable small powder packaging solutions

✔ Easy-to-maintain designs

✔ Cost-effective production advantages

✔ Comprehensive global support

For businesses seeking quality small powder packaging equipment, Yuheng provides machines designed for precision, reliability, and serviceability. Contact our packaging specialists today to discuss your requirements and discover how our solutions can meet your small powder packaging needs while providing long-term value and performance. Let us show you why companies worldwide trust Yuheng Technology for their critical packaging equipment requirements.