Powder Packaging Machine Price Guide and Comprehensive Solutions for Underfilled Packages

Introduction to Powder Packaging Technology

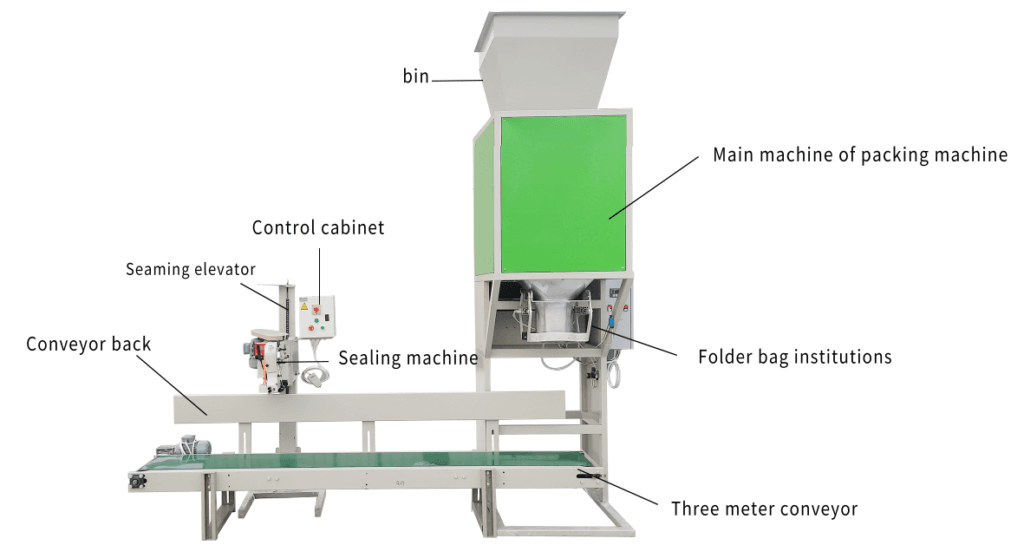

In today’s industrial landscape, powder packaging machines have become essential equipment for businesses across multiple sectors. These specialized packaging systems play a crucial role in food processing, pharmaceutical manufacturing, and chemical industries, ensuring accurate and efficient packaging of various powdered products. As a leading Chinese manufacturer with over a decade of experience, Yuheng Technology Co., Ltd has established itself as a trusted provider of high-quality powder packaging solutions that combine precision engineering with cost-effective manufacturing advantages for global customers.

Detailed Pricing Analysis for Powder Packaging Equipment

Understanding the investment required for powder packaging machinery is crucial for making informed purchasing decisions. The price range varies significantly based on automation level, production capacity, and specialized features. Semi-automatic powder packaging machines represent the most economical choice, typically priced between $25,000 and $60,000. These systems are ideal for small to medium-sized operations, offering basic packaging functionality with production capacities of 20-40 bags per minute. While requiring more operator involvement, they provide an excellent entry point into automated powder packaging solutions.

For businesses with higher production demands, automatic powder packaging systems offer enhanced capabilities at price points ranging from $60,000 to $140,000. These mid-range machines feature improved accuracy, touchscreen controls, and production capacities of 40-90 bags per minute. The increased automation significantly reduces labor requirements while improving packaging consistency, making them particularly suitable for growing operations.

At the premium end, high-speed automated powder packaging lines represent the most advanced solutions, with prices ranging from $140,000 to over $320,000. These sophisticated systems incorporate cutting-edge features like robotic integration and pharmaceutical-grade precision, capable of processing 90-160+ bags per minute. Yuheng Technology takes pride in offering these high-end systems with international quality standards while maintaining competitive pricing through efficient Chinese manufacturing processes.

Comprehensive Solutions for Underfilled Packages

Thorough Powder Supply System Inspection

Addressing underfilled packages begins with examining the entire powder supply chain. Operators should verify adequate powder levels in the supply hopper and check for blockages in feed tubes and transfer pipes. The condition of feeding mechanisms should be inspected to ensure proper operation. Yuheng powder packaging machines feature strategically placed inspection points that simplify troubleshooting procedures, helping maintain consistent powder flow and prevent underfilling issues.

Precision Parameter Adjustment Techniques

Achieving consistent fill levels requires careful adjustment of machine parameters to match specific powder characteristics. The auger speed or vibration frequency should be calibrated to maintain steady powder flow without causing compaction. Dosing parameters may need adjustment to compensate for variations in powder density, especially when switching between different products. Yuheng packaging systems include preset memory functions that store optimal parameters for different powder types, significantly reducing setup time and minimizing underfilling occurrences.

Sealing System Performance Verification

Proper sealing system performance is essential to prevent product loss that could lead to underfilled packages. Operators should regularly verify sealing temperature and pressure settings, as these can drift over time. The condition of sealing jaws should be inspected for wear or contamination that might compromise seal integrity. Yuheng packaging machines incorporate automatic temperature compensation systems that maintain consistent seal quality, helping ensure proper package fills.

Systematic Cleaning and Maintenance Protocols

Implementing comprehensive cleaning protocols is vital for maintaining consistent performance. Daily cleaning should focus on removing powder residues from all product contact surfaces, particularly in dosing and filling areas. Weekly maintenance should include thorough cleaning of dosing mechanisms and verification of moving components. Yuheng machines are designed with smooth surfaces and minimal crevices to facilitate thorough cleaning, while our technical support team can provide customized cleaning schedules tailored to specific production environments.

Dosing System Accuracy Maintenance

Regular verification of dosing accuracy is paramount to preventing underfilled packages. Mechanical components of the dosing system should be inspected for wear that could affect performance. Load cells and other measurement devices should be checked for proper calibration. Yuheng’s proprietary SmartDose technology automatically compensates for powder density variations, significantly reducing the likelihood of underfilling due to product characteristic changes.

Packaging Material Compatibility Assessment

The selection of appropriate packaging materials is often critical in preventing underfilled packages. Packaging films should be evaluated for their compatibility with specific powders, considering factors such as static electricity generation and powder adhesion tendencies. Yuheng Technology offers material compatibility testing services to help customers select optimal packaging films, ensuring consistent fill levels and overall packaging quality.

Yuheng Technology’s Commitment to Quality

With years of specialized experience in powder packaging solutions, Yuheng Technology has installed thousands of machines worldwide. Our commitment to quality begins at the design stage, incorporating features specifically aimed at preventing underfilling and other common packaging issues. All Yuheng powder packaging machines undergo rigorous testing before shipment, including extensive run-time trials with various powder types. Our global technical support network stands ready to assist customers with any operational challenges, while our Chinese manufacturing base allows us to provide these advanced solutions at competitive price points without compromising quality or reliability.

Selecting the Right Powder Packaging Solution

Choosing the appropriate powder packaging machine requires careful consideration of multiple factors including powder characteristics, production volume requirements, and accuracy specifications. Yuheng Technology’s packaging specialists work closely with customers to analyze their specific needs and recommend the most suitable solution. We consider all aspects of the packaging operation, from powder flow properties to production environment conditions. Whether you require a basic semi-automatic system or a fully automated high-speed packaging line, our team can guide you to the optimal solution that balances performance, reliability, and value.

Conclusion and Next Steps

Investing in quality powder packaging equipment and implementing proper solutions to prevent underfilled packages delivers substantial long-term benefits. Yuheng Technology stands ready to partner with your business to develop powder packaging solutions tailored to your specific requirements. Our combination of engineering expertise, rigorous quality control, and cost-effective manufacturing enables us to deliver exceptional value to customers worldwide. Contact our packaging specialists today to discuss how our solutions can address your powder packaging challenges while ensuring consistent, accurate results. Discover why businesses around the world trust Yuheng Technology for their powder packaging needs.