Corn Packaging Machinery: Price Guide & Essential Process Design Considerations

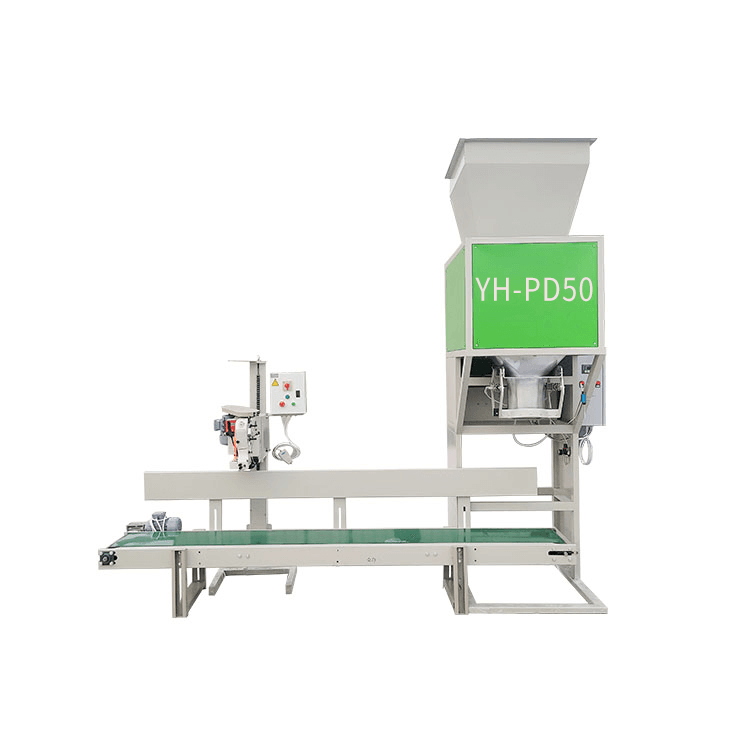

Corn packaging requires specialized equipment to ensure efficiency, durability, and product quality. As a leading Chinese manufacturer, Yuheng Technology Co., Ltd. designs high-performance corn packaging machines and grain packaging equipment that meet international standards while offering cost-effective solutions for global buyers.

How Much Does a Corn Packaging Machine Cost?

The price of corn packaging machinery varies based on automation level, capacity, and features. Below is a general pricing guide:

1. Basic Semi-Automatic Machines ($3,000 – $40,000)

- Speed: 10-30 bags per minute

- Best for: Small farms or low-volume packaging

- Features: Manual bag feeding, simple controls, basic weighing

2. Mid-Range Automatic Machines ($40,000 – $100,000)

- Speed: 30-60 bags per minute

- Best for: Medium-sized grain processing plants

- Features: Auto bag placement, touchscreen controls, dust-proofing

3. High-Speed Fully Automated Lines ($100,000 – $250,000+)

- Speed: 60-120+ bags per minute

- Best for: Large-scale corn packaging factories

- Features: Robotic bag handling, multi-head weighers, IoT monitoring

Why Choose Yuheng Technology?

✔ Affordable pricing with Chinese manufacturing efficiency

✔ Robust designs for long-term grain packaging use

✔ Customizable for different grain types (corn, wheat, rice)

✔ Global support network for maintenance & spare parts

Key Process Design Considerations for Corn Packaging

To maximize efficiency and product quality, manufacturers must optimize the packaging process flow. Here are critical factors:

1. Equipment Maintenance & Optimization

- Regular lubrication and inspection prevent breakdowns

- Adjust settings based on corn moisture levels

- Yuheng machines feature easy-access maintenance points

2. Cleaning & Quality Control

- Remove dust and debris to avoid contamination

- Use vibration sieves & air filters for cleaner packaging

- Yuheng’s self-cleaning systems reduce downtime

3. Precision Process Control

- Monitor filling weight accuracy (±0.5% to ±1%)

- Adjust sealing temperature for different bag materials

- Yuheng’s automated feedback system maintains consistency

4. Moisture & Storage Management

- Ideal corn moisture: 12-14% for safe packaging

- Use moisture sensors to prevent spoilage

- Yuheng machines support nitrogen flushing for extended shelf life

Why Proper Process Design Matters

- Reduces waste from improper sealing or weighing errors

- Improves efficiency with smoother production flow

- Ensures compliance with food safety regulations (FDA, EU standards)

- Lowers operational costs by minimizing downtime

Yuheng Technology’s Expertise:

✅ 15+ years in grain packaging machinery

✅ Turnkey solutions from cleaning to bagging

✅ Smart automation for higher productivity

Final Recommendation

When selecting a corn packaging machine, consider:

✔ Production volume (small, medium, or industrial scale)

✔ Automation needs (semi-auto vs. full robotic systems)

✔ Moisture & hygiene control for long-term storage

✔ After-sales support for maintenance & parts

Yuheng Technology provides reliable, cost-efficient corn and grain packaging machines designed for optimal process flow. Our machines ensure high-speed, precise, and hygienic packaging for global food producers.

Contact us today for a customized solution!