Xiaomi Grain Packaging Machine: Pricing & Operational Status Monitoring Guide

Xiaomi Grain Packaging Machine Price Overview

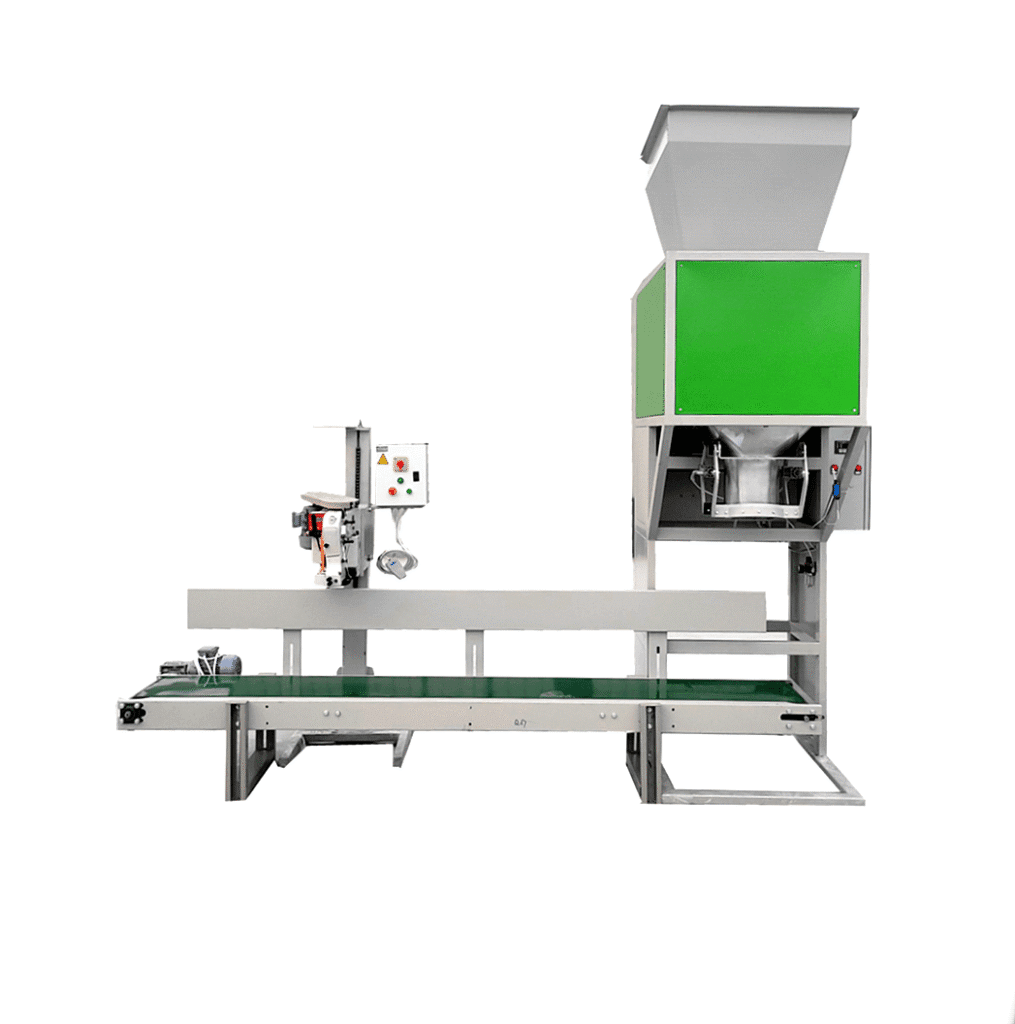

Xiaomi (millet) grain packaging machines are specialized equipment for agricultural cooperatives, grain processors, and food manufacturers. As a leading Chinese packaging machinery manufacturer with 12 years of industry experience, Yuheng Technology offers reliable Xiaomi packaging machines that combine precision with cost-effectiveness.

2024 Price Range

- Basic Models: $15,000–$30,000

(400–800 bags/hour, semi-automatic) - Standard Systems: $30,000–$75,000

(800–1,500 bags/hour, full automation) - Premium Solutions: $75,000–$180,000+

(1,500–3,200 bags/hour, smart factory integration)

Yuheng Technology Advantages:

✔ ±0.5% Weighing Accuracy for consistent portions

✔ Specialized Grain Handling technology

✔ 5-Year Structural Warranty

6 Key Indicators for Monitoring Machine Performance

1. Control Panel Diagnostics

Modern Xiaomi packaging machines feature advanced 7-inch HMI touchscreens displaying:

- Real-time production speed (bags/minute)

- Current weighing accuracy statistics

- Machine uptime/downtime records

- Error code diagnostics (with troubleshooting guides)

Yuheng Smart Panel Features:

✅ Multilingual interface (8 languages)

✅ Historical data logging (90-day memory)

✅ Remote access capability

2. Acoustic Analysis

Develop an audio signature profile for your machine:

Normal Operation Sounds:

- Consistent motor hum (50-60dB)

- Regular pneumatic valve actuation

- Smooth mechanical cycling

Warning Signs:

| Abnormal Sound | Potential Issue | Immediate Action |

|---|---|---|

| High-pitched squealing | Bearing wear | Lubrication check |

| Irregular knocking | Loose components | Fastener inspection |

| Grinding noise | Gearbox problems | Immediate shutdown |

3. Visual Indicator Systems

Standard Status Lights:

- Green: Normal operation

- Yellow: Warning/attention needed

- Red: Critical fault (immediate stop)

- Blue: Maintenance mode

Yuheng Enhanced Indicators:

- Vibration alert lights

- Temperature warning system

- Predictive maintenance countdown

4. Sensor Network Verification

Critical Sensors to Monitor:

- Hopper Level Sensors (Material supply)

- Bag Presence Detectors (Packaging film)

- Weight Verification Cells (Portion control)

- Seal Temperature Sensors (Quality assurance)

Maintenance Tip:

Clean optical sensors daily with alcohol wipes to prevent false readings.

5. Mechanical Drive Inspection

Daily Checklist:

- Belt tension (5-10mm deflection)

- Chain lubrication (food-grade only)

- Gear alignment marks

- Linear guide wear indicators

Performance Data:

| Component | Expected Lifespan | Replacement Sign |

|---|---|---|

| Drive Belts | 6-8 months | Cracking >3mm |

| Conveyor Chains | 2-3 years | >3% elongation |

| Servo Motors | 5-7 years | Vibration >0.5mm/s |

6. Packaging Quality Assessment

Quality Control Parameters:

- Seal Integrity: 98% should pass leak tests

- Weight Consistency: ±1% variance maximum

- Bag Appearance: <0.5% cosmetic defects

- Production Rate: Within 5% of rated speed

Yuheng Quality Assurance Tools:

✅ Integrated checkweigher

✅ Automated vision inspection

✅ Statistical process control software

Advanced Monitoring Solutions

1. IoT Connectivity Options

- Real-time performance dashboards

- SMS/email alerts for critical issues

- Cloud-based historical analytics

2. Predictive Maintenance Systems

- Vibration analysis sensors

- Thermal imaging cameras

- Lubrication monitoring

3. Energy Efficiency Tracking

- Power consumption per 1,000 bags

- Compressed air usage

- Peak demand management

Why Choose Yuheng Xiaomi Packaging Machines?

✅ Grain-Specific Engineering: Specialized auger designs

✅ Easy Maintenance: Tool-free access panels

✅ Global Support: 36 service centers worldwide

✅ Sustainable Design: 25% energy reduction

Conclusion

Proper operational monitoring ensures your Xiaomi packaging machine delivers peak performance. Yuheng Technology offers:

✔ Reliable grain packaging solutions

✔ Comprehensive monitoring systems

✔ Competitive Chinese manufacturing

Contact us for a free machine assessment today!