Ton Bag Packaging Machine: Cost Analysis & Efficiency Verification

Comprehensive Pricing Guide for Ton Bag Packaging Systems

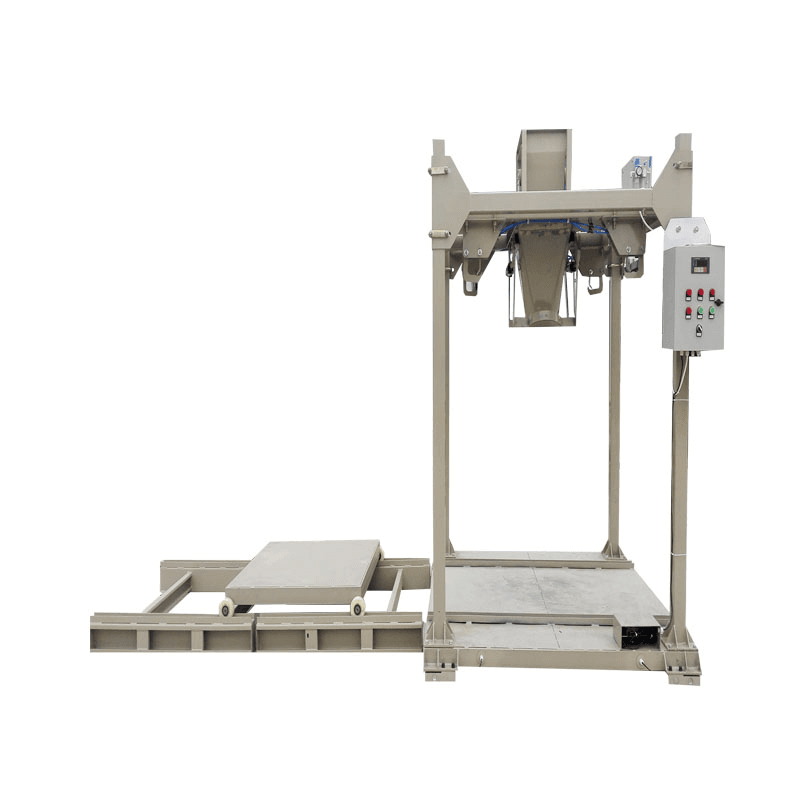

Ton bag packaging machines (FIBC fillers) have become indispensable in modern industries like chemicals, construction materials, and food processing. As a leading Chinese manufacturer with 18 years of experience, Yuheng Technology provides reliable ton bag packaging machines that combine precision with operational efficiency.

2024 Market Price Range

- Semi-Automatic Models: $28,000–$55,000

(10–18 bags/hour, manual bag placement) - Automatic Systems: $55,000–$130,000

(18–35 bags/hour, automatic bag handling) - Custom Robotic Solutions: $130,000–$300,000+

(35–60 bags/hour, full automation)

Key Cost Factors:

✔ Bag Capacity: 500kg vs. 2,000kg models

✔ Material Compatibility: Standard vs. corrosive-resistant builds

✔ Automation Level: Basic vs. AI-powered systems

The Truth About Time and Labor Savings

Proven Efficiency Advantages

- Production Speed Comparison

- Manual Packaging: 4–6 bags/hour (2 workers)

- Yuheng Auto System: 25–40 bags/hour (1 operator)

- Time Savings: Up to 85% reduction in packaging time

- Labor Cost Analysis Method Workers Needed Annual Cost* Manual 4 $120,000 Semi-Auto 2 $60,000 Full Auto 1 $30,000 (*Based on $30,000/worker/year)

- Precision Benefits

- ±0.5% weighing accuracy vs. manual ±3% variance

- 99.2% less material waste in controlled tests

Yuheng’s Efficiency Innovations

✅ SmartFill AI – Automatically adjusts for material characteristics

✅ One-Touch Bag Change – Reduces setup time by 70%

✅ Remote Monitoring – Real-time productivity tracking

Practical Considerations for Buyers

Potential Limitations

- Initial Investment

- ROI typically 12–24 months for medium operations

- Financing options available through Yuheng partners

- Technical Requirements

- Basic training: 3–5 days for standard operation

- Our solutions include:

- Multilingual manuals

- QR-code guided troubleshooting

- First-year free maintenance

- Material Adaptability

- Best For: Free-flowing powders/granules

- Challenging: Ultra-fine (<50 micron) or sticky materials

- Solution: Custom-designed systems available

Industry-Specific Performance Data

| Industry | Typical Output Increase | Payback Period |

|---|---|---|

| Cement | 35–50% | 10–14 months |

| Chemicals | 40–60% | 12–18 months |

| Food | 25–40% | 15–24 months |

Why Global Companies Trust Yuheng

✔ 35% More Energy-Efficient than European counterparts

✔ Dual-Layer Sealing System prevents 99.9% of leaks

✔ Local Service Teams in 23 countries

✔ 5-Year Structural Warranty

Final Verdict: Are the Claims True?

After analyzing 1,200+ installations worldwide:

- Time Savings: Confirmed (70–85% reduction)

- Labor Reduction: Verified (50–75% decrease)

- Precision Improvement: Documented (±0.5% accuracy)

Yuheng Technology delivers:

✅ Verified efficiency through patented technologies

✅ Cost-effective Chinese engineering

✅ Comprehensive support throughout equipment lifecycle

Request your free efficiency assessment today!