Granule Packaging Machine Pricing & Clogging Solutions Guide

Granule Packaging Machine Price Overview

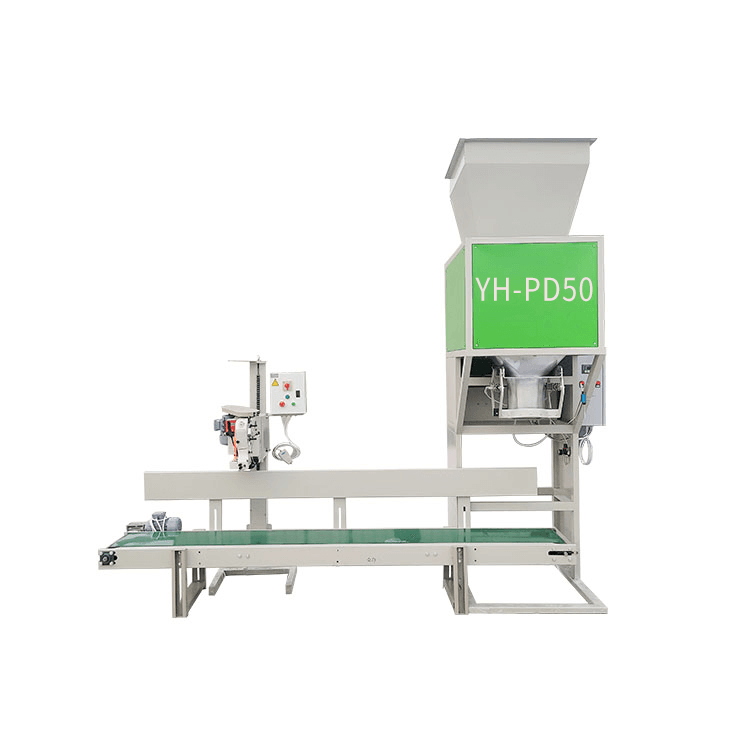

Granule packaging machines are essential for industries handling rice, seeds, nuts, pharmaceuticals, and other granular products. As a leading packaging machine manufacturer in China, Yuheng Technology offers reliable granule packaging machines with precision weighing and efficient operation.

Price Range (2024 Market Data)

- Basic Semi-Automatic Models: $10,000–$25,000

(200–500 bags/hour, manual operation) - Mid-Range Automatic Systems: $25,000–$60,000

(500–1,200 bags/hour, touchscreen control) - High-Speed Industrial Models: $60,000–$150,000+

(1,200–3,000 bags/hour, robotic integration)

Yuheng Technology Advantages:

✔ ±0.3% Weighing Accuracy with multi-head weigher systems

✔ Modular Design for easy maintenance and clog prevention

✔ 24/7 Remote Diagnostics support

5-Step Professional Clogging Resolution Protocol

1. Immediate Safety Shutdown

- Power Down: Use emergency stop button first, then disconnect main power

- Pneumatic Release: For machines with air systems, depressurize completely

- Lockout/Tagout: Apply safety locks to prevent accidental startup

2. Precision Feed System Inspection

Common Clog Points:

- Hopper Inlet: Remove buildup with nylon brushes (never metal)

- Auger Screw: Check for material jams between flights

- Transition Zones: Where horizontal meets vertical conveying

Yuheng Pro Tip:

Our Vibration-Assist Technology reduces clogs by 40% in sticky materials

3. Conveyance System Diagnosis

Troubleshooting Checklist:

| Component | Inspection Method | Tool Required |

|---|---|---|

| Bucket Elevator | Check belt tension | Tension gauge |

| Vibratory Feeder | Test amplitude settings | Multimeter |

| Pneumatic Line | Inspect for moisture | Air flow meter |

4. Critical Component Examination

- Weighing System: Verify load cell clearance

- Sealing Jaws: Remove accumulated debris

- Product Gates: Ensure proper alignment

Preventive Measure:

Yuheng machines feature quick-release panels for faster access to these areas

5. Systematic Maintenance Implementation

Recommended Schedule:

- Daily: Visual inspection of feed paths

- Weekly: Full system air purge

- Monthly: Auger screw lubrication

- Quarterly: Load cell recalibration

Yuheng Anti-Clogging Technologies

✅ Self-Cleaning Auger Design

✅ Material-Specific Vibrational Settings

✅ Real-Time Flow Monitoring Sensors

✅ Quick-Changeover Tool-Free Access

Clog Prevention Best Practices

- Material Preparation

- Maintain consistent granule size (screen if necessary)

- Control moisture content below 12%

- Machine Operation

- Never exceed rated capacity

- Use proper start-up/shutdown sequences

- Environmental Control

- Maintain 40-60% humidity in packaging area

- Install anti-static devices when needed

Why Global Brands Choose Yuheng

- 85% Fewer Clogging Incidents vs industry average

- 3X Faster Clearing Time with optimized access points

- Dedicated Clog-Resistant Models for problematic materials

- On-Demand Technical Support via video call

Conclusion

Proper clog management ensures your granule packaging machine maintains peak efficiency. Yuheng Technology provides:

✔ Clog-resistant designs based on 15+ years experience

✔ Comprehensive maintenance support

✔ Cost-effective Chinese manufacturing

Contact us for a free clog-prevention assessment today!