Powder Packaging Machine Price Guide & Proper Disassembly Methods

How Much Does a Powder Packaging Machine Cost?

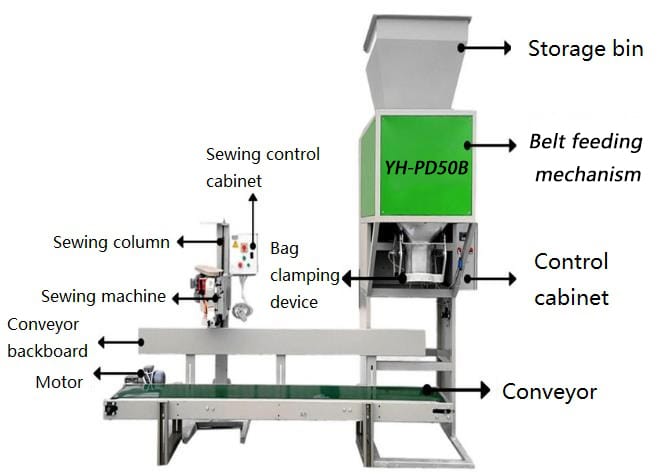

Powder packaging machines are essential equipment for pharmaceutical, food, and chemical industries. As a leading packaging machine manufacturer in China, Yuheng Technology provides high-quality powder packaging machines with precision dosing and excellent sealing performance.

Price Range for Powder Packaging Machines

- Semi-Automatic Models: $3,000–$30,000

(200–500 bags/hour, manual operation) - Automatic Systems: $30,000–$80,000

(500–1,200 bags/hour, touchscreen control) - High-Speed Fully Automated Lines: $80,000–$200,000+

(1,200–3,000 bags/hour, robotic integration)

Yuheng Technology Advantages:

✔ ±0.2% Dosing Accuracy with patented vibration technology

✔ CE & ISO Certified manufacturing standards

✔ 30% Longer Lifespan than industry average

6-Step Professional Disassembly Guide for Powder Packaging Machines

Proper disassembly is crucial for maintenance, cleaning, and part replacement. Follow these steps to ensure safety and prevent damage:

1. Preparation & Documentation

- Review the manual: Study Yuheng’s technical documentation for model-specific instructions

- Create a workspace: Designate a clean, well-lit area with proper ventilation

- Gather tools: Prepare metric hex keys, torque wrenches, and anti-static equipment

2. Power Safety Procedures

- Complete shutdown: Turn off main power switch and unplug from electrical supply

- Pneumatic system depressurization: Release all air pressure (for machines with pneumatic components)

- Capacitor discharge: Wait 15 minutes after power-off for electrical components to fully discharge

3. Thorough Cleaning Process

- Dry cleaning: Use vacuum cleaners with HEPA filters to remove 95% of surface powder

- Wet cleaning: Apply food-grade, non-corrosive cleaners for residue removal

- Special attention areas: Focus on dosing screws, hoppers, and sealing jaws

4. External Casing Removal

- Screw organization: Use magnetic trays to prevent loss of fasteners

- Cable management: Label all electrical connections before disconnection

- Panel storage: Place removed panels on padded surfaces to prevent scratching

5. Internal Component Disassembly

Critical Components Handling:

- Dosing system: Carefully extract auger screws without bending

- Weighing cell: Protect load cells from impact during removal

- Sealing mechanism: Note jaw alignment marks before disassembly

6. Parts Organization System

- Digital documentation: Photograph each step for reassembly reference

- Sorting containers: Use compartmentalized boxes with labeled sections

- Protective measures: Apply anti-corrosion spray to exposed metal surfaces

Yuheng Technology’s Disassembly Support

✅ Color-coded components for easy identification

✅ QR code tracking system for all major parts

✅ Video tutorials available through our customer portal

✅ 3D interactive manuals showing explosion diagrams

Common Disassembly Mistakes to Avoid

- Rushing the process (leads to broken connectors)

- Using incorrect tools (causes stripped screws)

- Neglecting static control (risks electronic damage)

- Mixing lubrication points (contaminates systems)

Maintenance Frequency Recommendations

| Component | Inspection Interval | Service Life |

|---|---|---|

| Dosing Auger | 250 operating hours | 2–3 years |

| Load Cells | 500 hours | 5–7 years |

| Sealing Jaws | 100 hours | 1–1.5 years |

| Control Board | Annual | 7–10 years |

Why Choose Yuheng Technology?

- Tool-less access design on 60% of components

- Modular construction simplifies disassembly

- Global spare parts network (48-hour delivery guarantee)

- Free lifetime technical support for proper maintenance

Conclusion

Proper disassembly extends your powder packaging machine’s service life and maintains accuracy. Yuheng Technology machines feature:

✔ User-friendly disassembly points

✔ Premium corrosion-resistant materials

✔ Comprehensive support documentation

Contact our engineers for personalized disassembly training!