How Much Does a Valve Bag Packaging Machine Cost? Common Causes of Weighing Instability

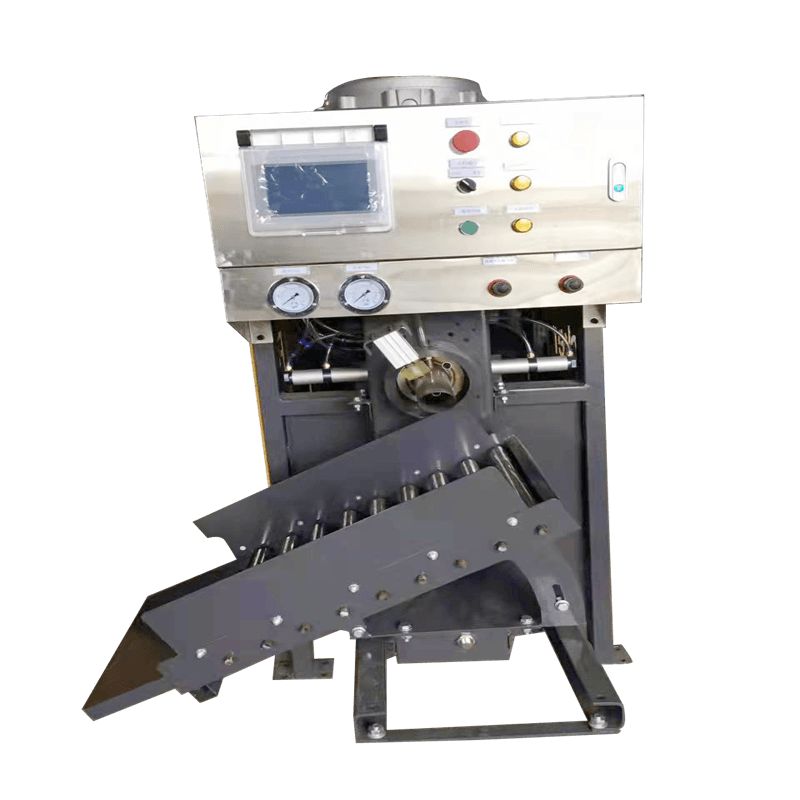

Valve bag packaging machines are essential equipment in industries such as cement, chemicals, and food processing. As a leading packaging machine manufacturer in China, Yuheng Technology specializes in producing high-precision valve bag packaging machines that combine efficiency with reliability.

This article will address two critical questions:

- Price factors for valve bag packaging machines

- Key reasons behind weighing instability and how to resolve them

Valve Bag Packaging Machine Price Range

The cost of a valve bag packaging machine typically ranges from $15,000 to $80,000, depending on:

- Automation Level

Semi-automatic models start around $15,000, while fully automated systems with robotic palletizing can exceed $80,000. - Production Capacity

Machines packing 600-1,200 bags per hour command higher prices. - Material Compatibility

Specialized models for abrasive materials (e.g., cement) or food-grade applications cost 20-30% more.

Yuheng Technology Advantages:

✔ Cost-Effective Manufacturing – As a Chinese OEM, we offer competitive pricing without compromising quality

✔ CE & ISO Certified – Our machines meet global safety and performance standards

✔ Custom Solutions – We adapt machines for unique materials like carbon black or titanium dioxide

5 Common Causes of Weighing Instability

Weighing accuracy is crucial for valve bag packaging. Here are the primary causes of instability and their solutions:

1. Material Characteristics

- Problem: Variations in density (e.g., flour vs. granulated sugar) or poor flowability cause inconsistent filling

- Solution:

✓ Use Yuheng’s adaptive vibration technology to improve material flow

✓ Install our density compensation system for precision dosing

2. Load Cell Malfunction

- Problem: Damaged or dirty sensors provide erratic weight readings

- Solution:

✓ Our machines feature IP67-rated load cells resistant to dust and moisture

✓ Regular calibration with Yuheng’s auto-zeroing technology

3. Improper Calibration

- Problem: Temperature changes or mechanical stress alter calibration over time

- Solution:

✓ Yuheng’s touchscreen interface simplifies weekly calibration

✓ Optional remote calibration monitoring via IoT connectivity

4. Mechanical Wear

- Problem: Loose bearings or worn feed screws cause positional drift

- Solution:

✓ Our laser-aligned frame construction minimizes vibration

✓ Scheduled maintenance reminders through Yuheng’s predictive maintenance system

5. Environmental Factors

- Problem: Air currents, vibration, or electrical interference affect sensors

- Solution:

✓ Integrated anti-vibration mounts and EMI shielding in all Yuheng machines

Why Choose Yuheng Technology?

✅ 15+ Years in valve bag packaging solutions

✅ <0.5% Weighing Accuracy – Industry-leading precision

✅ 24/7 Global Technical Support

✅ 30% Faster ROI through energy-efficient designs

Conclusion

Understanding weighing instability causes helps maintain packaging accuracy. For high-performance valve bag packaging machines, Yuheng Technology delivers:

✔ Stable weighing through advanced sensor technology

✔ Cost savings via Chinese manufacturing efficiency

✔ Long-term reliability with ISO-certified components

Contact us today for a machine demonstration!