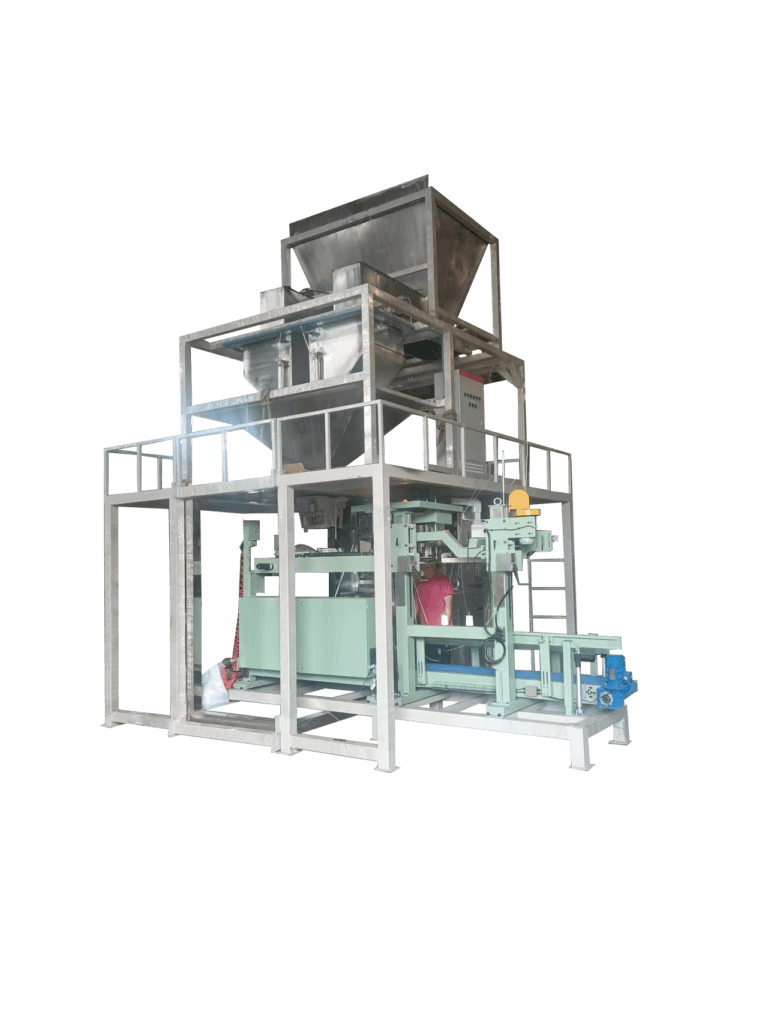

Automatic Packaging Machine Price and Seasoning Packaging Solutions

For food manufacturers worldwide considering packaging automation, two key questions dominate their research: What is the investment range for automatic packaging machines? and How effectively can they handle diverse seasoning products? As an established Chinese packaging equipment manufacturer with 15+ years of global export experience, Yuheng Technology Co., Ltd presents this detailed guide to help international buyers navigate their packaging automation decisions.

Comprehensive Price Analysis of Automatic Packaging Machines

The cost spectrum for automatic packaging equipment varies significantly based on production capacity and technological sophistication. Entry-level models from Yuheng Technology, priced between $25,000 and $50,000, offer reliable solutions for small-scale spice producers and regional brands. These systems typically handle 30-60 packages per minute with basic weighing and bag-forming capabilities, representing an accessible entry point into packaging automation.

Mid-range packaging systems, ranging from $55,000 to $120,000, cater to growing food processing businesses requiring higher output. These machines incorporate enhanced features like multi-head weighing systems for improved accuracy, dust-proof designs for powder containment, and more sophisticated control interfaces. The increased investment translates to better production consistency and reduced material waste – crucial factors for seasoning manufacturers maintaining product quality standards.

At the premium tier, high-capacity production lines priced from $130,000 to $300,000+ serve large-scale seasoning manufacturers with demanding throughput requirements. These advanced systems integrate cutting-edge technologies like AI-powered portion control that automatically adjusts for product density variations, ensuring consistent fill weights even with challenging materials. The automation level minimizes human intervention while maximizing output quality, making them ideal solutions for international food brands supplying global markets.

Yuheng Technology’s packaging machines demonstrate the value proposition of Chinese manufacturing by combining robust construction with competitive pricing. Our equipment features food-grade 304 stainless steel contact surfaces meeting international hygiene standards, achieves exceptional measurement accuracy within ±0.2%, and includes an industry-leading 5-year warranty on critical components. These quality assurances, combined with 30-40% cost savings compared to European equivalents, make our solutions particularly attractive to international buyers balancing quality and budget considerations.

Advanced Seasoning Packaging Capabilities

Modern automatic packaging machines have transformed seasoning production by handling an unprecedented variety of products with precision and efficiency. These versatile systems accommodate everything from coarse, irregularly shaped spices to ultra-fine powdered blends, addressing the complete spectrum of flavoring products:

Whole Spices and Herbs

The machines expertly package bulky, irregular items like:

- Star anise and cinnamon sticks requiring gentle handling

- Peppercorns and coriander seeds needing vibration-assisted flow

- Delicate bay leaves and rosemary stems demanding careful orientation

Powdered and Granular Seasonings

Precision systems ensure accurate portioning of:

- Free-flowing salts and sugars

- Hygroscopic ingredients like MSG and chicken powder

- Challenging powders such as chili and turmeric that tend to dust

Complex Blended Products

Sophisticated controls maintain consistent ratios in:

- Multi-component spice mixes (curry powders, barbecue rubs)

- Layered soup bases and instant drink formulations

- Specialty blends combining powders, flakes, and granules

Specialty Seasoning Items

Adaptable designs accommodate unique products like:

- Crystal sugars and rock salts requiring heavy-duty bagging

- Fragile tea leaves and herbal blends needing gentle treatment

- Oily seasoning pastes and blended sauces with special handling needs

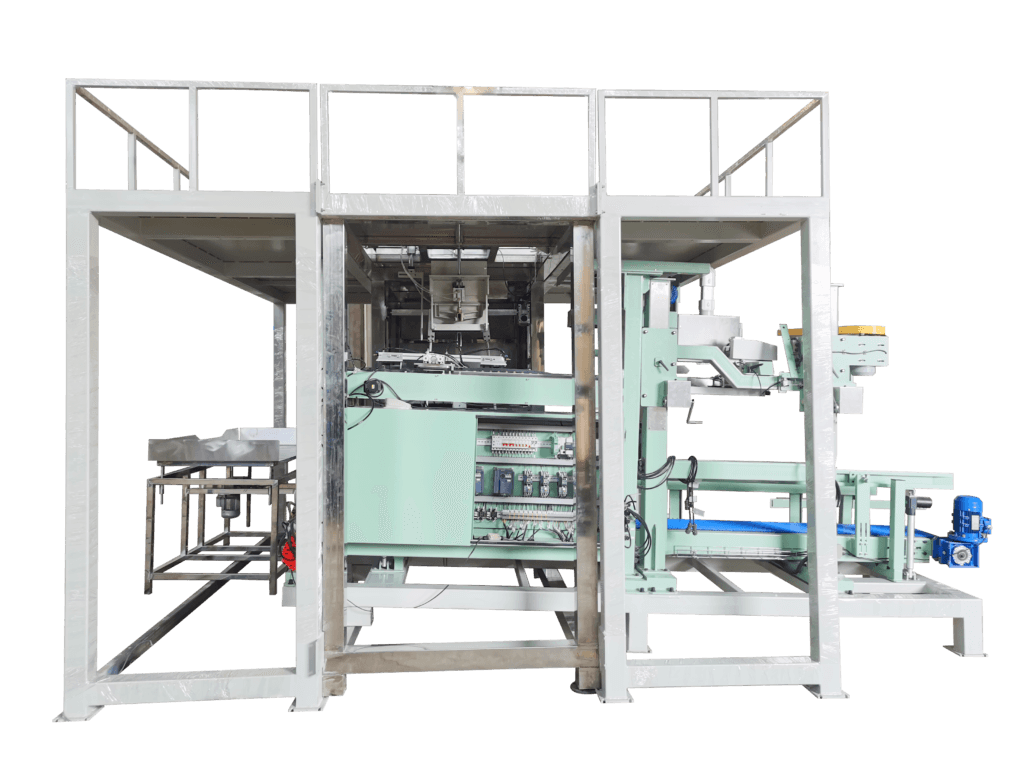

Critical Features for Optimal Seasoning Packaging

1. Precision Measurement Systems

Advanced load cell technology combined with intelligent software algorithms ensures each package contains exactly the specified amount, crucial for maintaining consistent flavor profiles. Yuheng machines automatically compensate for product density variations that commonly occur with hygroscopic seasonings.

2. Material-Specific Adaptations

Our engineers have developed specialized solutions for common seasoning challenges:

- Anti-static systems prevent fine powders from clinging to surfaces

- Gentle vibration feeders preserve delicate herb structures

- Specialized auger designs handle sticky blends without smearing

- Dedicated dust collection maintains clean operation with powdery products

3. Hygienic Operation Design

Food safety considerations are paramount in seasoning packaging:

- Fully enclosed construction prevents external contamination

- Smooth, radiused surfaces with minimal seams for easy cleaning

- Optional CIP (Clean-in-Place) systems for frequent product changeovers

- Compliance with international food safety standards (FDA, CE)

4. Intelligent Control Systems

User-friendly interfaces simplify operation while providing advanced functionality:

- Recipe memory stores parameters for hundreds of products

- Production tracking logs batch data for quality control

- Remote diagnostics enable quick troubleshooting

- Multi-language support for international operations

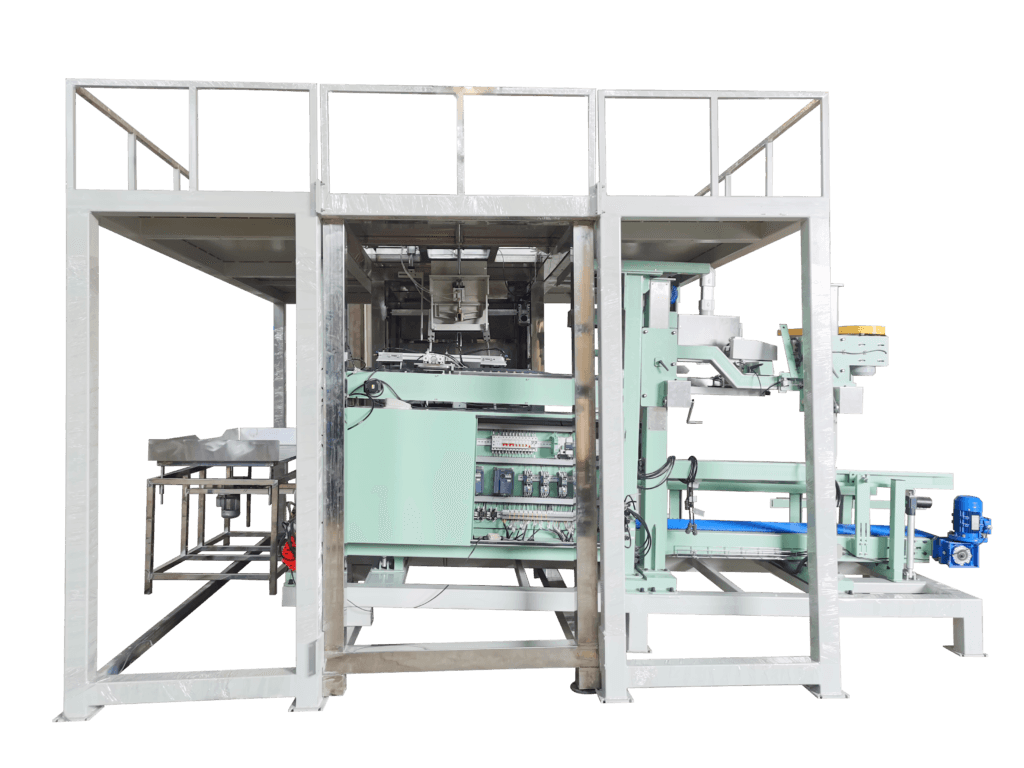

Why Seasoning Manufacturers Worldwide Choose Yuheng

- Unmatched Versatility

Our machines handle the complete spectrum of seasoning types without requiring mechanical modifications, from coarse peppercorns to ultra-fine powders. - Product Integrity Protection

Advanced sealing technologies and gentle handling preserve volatile aromas and prevent flavor degradation during packaging. - Operational Efficiency

Automated systems reduce labor requirements by up to 70% compared to manual packaging while increasing output consistency. - Customized Solutions

We offer tailored configurations addressing unique regional seasoning characteristics and local packaging preferences. - Global Support Network

Yuheng provides comprehensive international support including:

- Multilingual operation manuals and training materials

- Worldwide spare parts availability

- Local technician partnerships in key markets

- 24/7 remote assistance

Technical Specifications

- Bag Styles: Stand-up pouches, flat bags, gusseted packages

- Material Compatibility: Various films, foils, and biodegradable options

- Power Requirements: Standard 380V/50Hz (configurable to regional standards)

Additional Considerations for International Buyers

When evaluating automatic packaging machines for seasoning applications, also consider:

- Local regulations regarding food contact materials

- Climate control requirements for hygroscopic products

- Shelf-life optimization through packaging material selection

- Brand differentiation through unique package shapes and features

- Future expansion capabilities as product lines grow

Yuheng Technology stands ready to assist seasoning producers worldwide in selecting and implementing the ideal packaging automation solution for their specific needs. Our team offers personalized consultations to address unique product challenges and help businesses transition smoothly from manual to automated packaging operations. With our combination of engineering expertise, competitive pricing, and global support infrastructure, we make advanced packaging automation accessible to seasoning manufacturers of all sizes across international markets.

If you want to know more about the equipment configuration and other details, please feel free to communicate with us