Pre-Made Bag Packaging Machine Price and Common Troubleshooting Guide

For manufacturers considering packaging automation, two critical questions often arise: What is the price range for pre-made bag packaging machines? and What common issues might occur during operation? As an experienced Chinese packaging equipment manufacturer with a global client base, Yuheng Technology Co., Ltd provides this comprehensive guide to help international buyers understand costs and maintenance solutions for these efficient packaging systems.

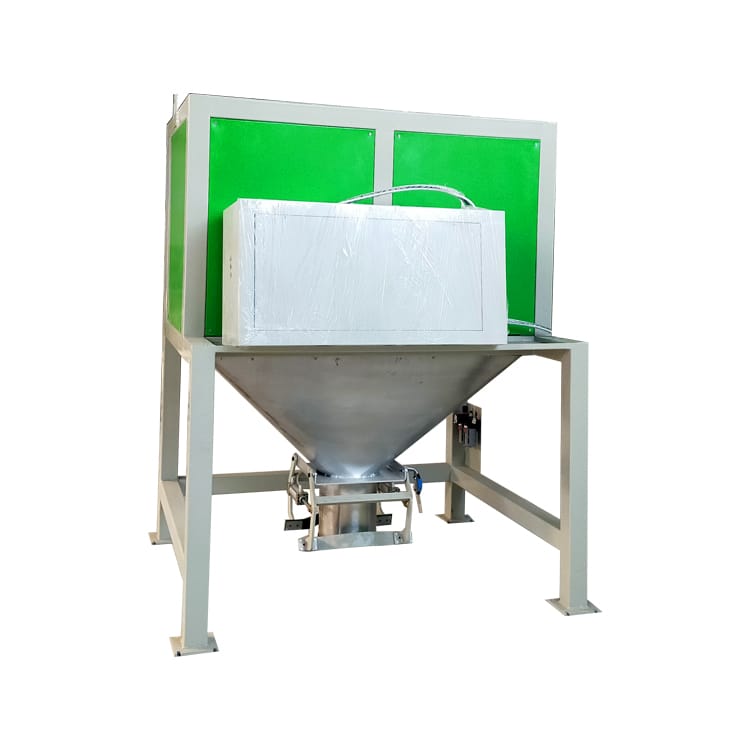

Price Range for Pre-Made Bag Packaging Machines

- Basic Semi-Automatic Models ($30,00-$60,00)

- Capacity: 20-40 bags/minute

- Suitable for: Small food producers, pharmaceuticals

- Features: Manual bag loading, basic sealing

- Standard Automatic Systems ($65,00-$130,00)

- Capacity: 50-100 bags/minute

- Includes: Auto bag feeding, touchscreen controls

- Ideal for: Medium-sized processing plants

- High-Speed Production Lines ($140,00-$300,000+)

- Capacity: 120-250 bags/minute

- Technology: Robotic integration, vision inspection

- Designed for: Large-scale food manufacturers

Yuheng machines offer:

✔ 304 stainless steel construction

✔ ±0.3% weighing accuracy

✔ 5-year structural warranty

Common Operational Issues and Professional Solutions

1. Film Material Misalignment During Feeding

When film consistently shifts despite adjusting rollers and tension rods:

- For upper film deviation: Adjust the upper triangular plate clockwise

- For lower film deviation: Adjust the upper triangular plate counterclockwise

- Preventive measure: Install Yuheng’s auto-correcting guidance system

2. Slow Heating or Inadequate Temperature

Troubleshooting steps:

- Check magnetic starter contact points

- Verify all three power phases are active

- Test heater resistance values

- Inspect SSR (Solid State Relay) functionality

Yuheng solution: Our machines feature dual backup heating circuits

3. Insufficient Vacuum Levels

When packaged products show poor vacuum:

- Immediate action: Replace contaminated vacuum pump oil

- Secondary checks:

→ Inspect vacuum solenoid valves

→ Examine chamber gasket condition

→ Test pump motor performance

Pro tip: Yuheng machines include vacuum level sensors with real-time alerts

4. Irregular Seal Quality

Address inconsistent seals by:

- Calibrating jaw temperature monthly

- Replacing worn Teflon sealing strips

- Adjusting pressure cylinder settings

- Checking compressed air quality

5. Intermittent Bag Feeding Issues

Resolve feeding problems through:

- Cleaning suction cups regularly

- Adjusting vacuum generator pressure

- Replacing damaged feed claws

- Verifying photoelectric sensor alignment

Why International Clients Trust Yuheng Technology

- Smart Diagnostics: 85% common issues identifiable via touchscreen

- Quick-Change Design: <10 minute format adjustments

- Global Support: Multilingual technical assistance

- Cost Advantage: 35% savings vs European equivalents

If you want to know more about the equipment configuration and other details, please feel free to communicate with us