How Much Does a Fully Automatic Packaging Machine Cost? A Comprehensive Guide to Evaluating Quality

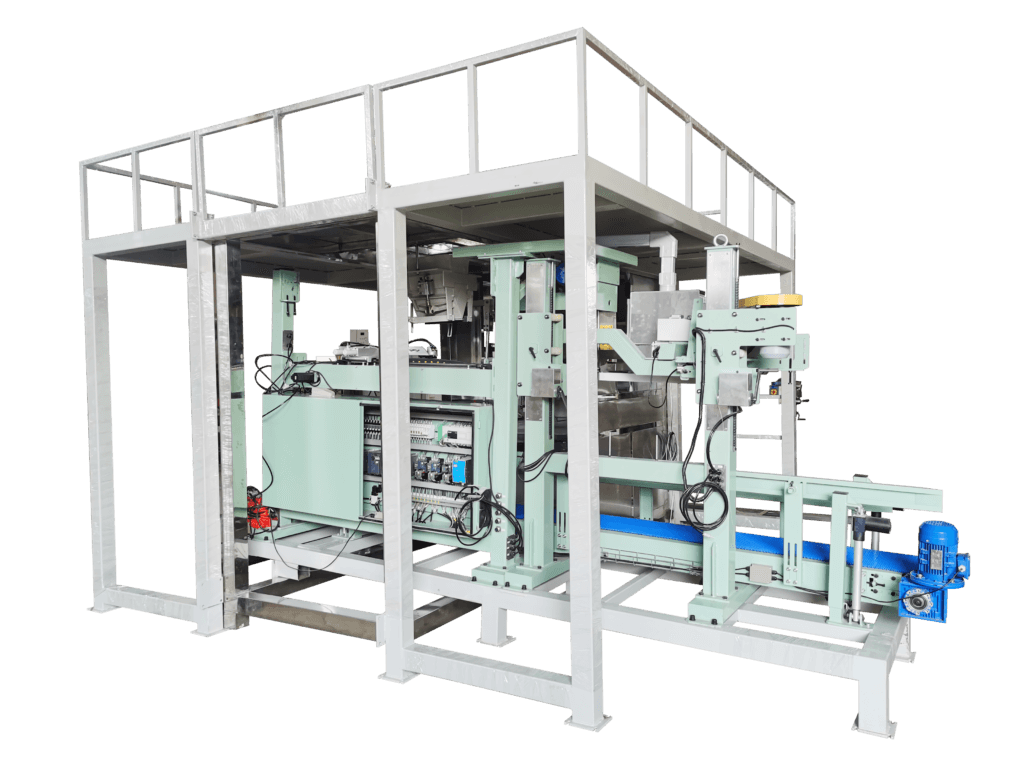

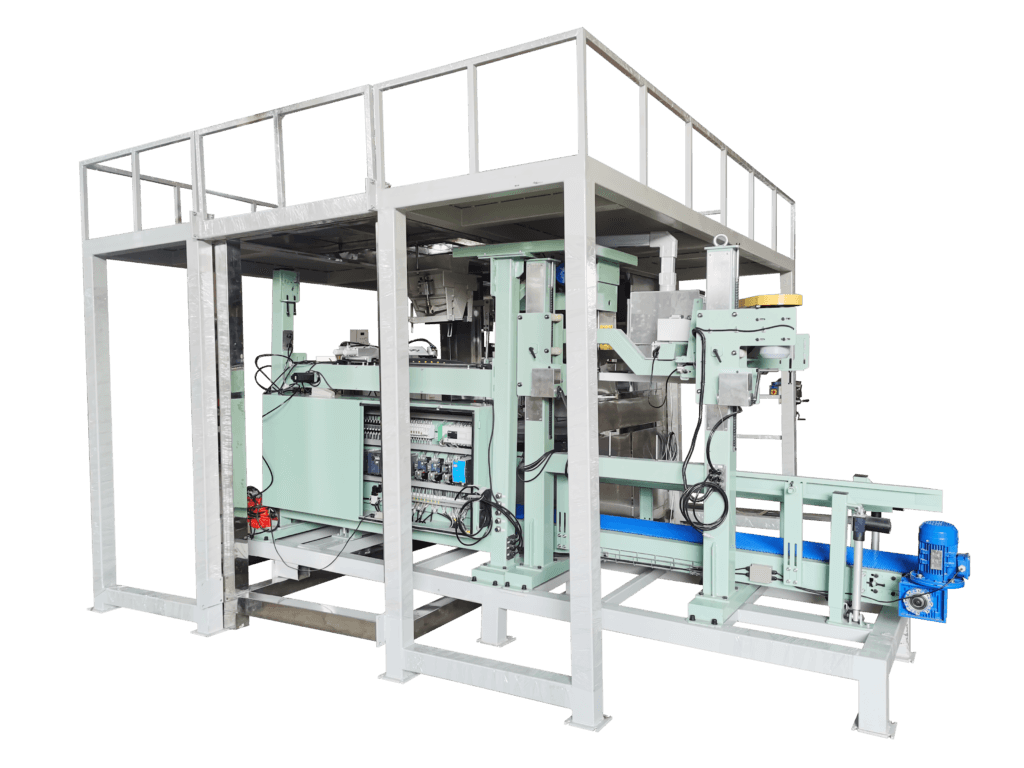

For businesses looking to automate their packaging operations, understanding the investment required and how to assess machine quality are two of the most critical considerations. As a leading Chinese manufacturer with extensive experience serving international markets, Yuheng Technology Co., Ltd provides this in-depth guide to help global buyers navigate the world of fully automatic packaging machines.

Understanding the Price Range of Fully Automatic Packaging Machines

The cost of fully automatic packaging machines varies significantly based on their capabilities and production capacity. Entry-level models from Yuheng Technology typically range between $25,000 and $50,000, offering reliable performance for small to medium businesses packaging dry goods like seeds, grains, or basic food products. These machines feature essential automation with servo controls and semi-enclosed designs that provide good value for money.

Mid-range systems priced from $55,000 to $120,000 are better suited for established food and pharmaceutical producers requiring higher output. These machines incorporate more advanced features like touchscreen human-machine interfaces (HMIs), automatic product detection systems, and enhanced precision weighing mechanisms. The increased investment brings improved efficiency and consistency to packaging operations.

At the premium end of the market, fully automated production lines costing $130,000 to $300,000+ are designed for large-scale FMCG manufacturers with demanding production requirements. These high-speed systems can handle 200-500 packages per minute and often incorporate cutting-edge technologies like robotic integration and AI-powered quality control systems that automatically detect and reject defective packages.

Yuheng Technology’s packaging machines stand out in the global market by combining robust construction with competitive pricing. Our machines feature 304/316L stainless steel contact surfaces that meet international hygiene standards, achieve measurement accuracies within ±0.2%, and come with an industry-leading 5-year warranty on core components – advantages that demonstrate the value of Chinese manufacturing when quality engineering meets cost efficiency.

Key Factors for Evaluating Packaging Machine Quality

When comparing different fully automatic packaging machines, several critical factors can help distinguish truly high-quality equipment from inferior alternatives:

1. Material Construction and Build Quality

The foundation of any reliable packaging machine lies in its construction. High-quality machines use substantial 2-3mm thick stainless steel (typically 304 grade) for their frames and product contact surfaces. This provides the necessary durability for continuous industrial operation while meeting food safety requirements. In contrast, lower quality machines may use thinner carbon steel with spray paint finishes that are more prone to rust and wear over time.

Yuheng Technology goes a step further by offering marine-grade 316L stainless steel options for operations in corrosive environments or when packaging acidic products. This attention to material selection reflects our commitment to building machines that last, even in challenging operating conditions.

2. Critical Components and Their Origins

The quality of individual components significantly impacts overall machine performance and longevity. Key elements to examine include:

- Servo Motors: Premium machines use reputable Japanese or German brands known for their reliability and precision

- PLC Systems: Look for established automation brands like Siemens or Omron for the control systems

- Bearings and Mechanical Parts: High-quality machines incorporate components from leading manufacturers like SKF or NSK

These premium components may cost more initially but dramatically reduce downtime and maintenance costs over the machine’s lifespan. Yuheng Technology carefully selects each component based on rigorous testing to ensure optimal performance and reliability in our packaging systems.

3. Design Details and Finishing

Beyond just technical specifications, the thoughtful execution of design details often separates exceptional machines from average ones:

- Smooth, radius-treated edges that improve safety during operation and maintenance

- Logical component layouts that allow easy access for cleaning and servicing

- Consistent panel gaps with tolerances under 1mm, indicating precise manufacturing

- Well-organized cable management that prevents interference and simplifies troubleshooting

These seemingly small details collectively contribute to better user experience, easier maintenance, and ultimately, higher productivity over the machine’s operational life.

4. Manufacturer Reputation and Support

The company behind the machine is just as important as the equipment itself. Reputable manufacturers like Yuheng Technology typically have:

- ISO 9001 quality management certification

- CE/FDA compliance for relevant markets

- 10+ years of industry experience

- Verifiable client references across different regions

Equally important is the after-sales support structure. Yuheng provides comprehensive support including:

- Multilingual operation manuals and instructional videos

- Remote troubleshooting assistance

- Global spare parts availability

- On-site training options

This level of support is particularly valuable for international buyers who need reliable local service regardless of their location.

5. Performance Validation Through Testing

Before making a final decision, request live demonstrations or factory acceptance tests that verify:

- Stable operation over continuous 8-hour production runs

- Consistent package weight accuracy and seal quality

- Efficient changeover between different products or package sizes

- Noise levels during operation

Yuheng Technology encourages potential buyers to visit our facilities in China to see our manufacturing processes firsthand and test machines with their actual products. This transparency builds confidence in the equipment’s capabilities before purchase.

Why Global Buyers Choose Yuheng Technology

International customers consistently select Yuheng’s fully automatic packaging machines for several compelling reasons:

Cost Efficiency Without Compromise

Our machines deliver comparable performance to European brands at 30-40% lower total ownership costs, combining competitive initial pricing with lower long-term maintenance expenses.

Adaptability for Local Needs

We understand that packaging requirements vary by market. Our engineering team works closely with clients to customize machines for specific regional preferences, package sizes, or product characteristics.

Quality Assurance

Beyond our own rigorous quality control, we welcome third-party inspections and provide comprehensive documentation including material certifications and test reports.

If you want to know more about the equipment configuration and other details, please feel free to communicate with us