Granule Packaging Machine Price and Key Differences from Powder Packaging Machines

When selecting packaging equipment for solid materials, manufacturers worldwide often need answers to two important questions: What is the typical price range for granule packaging machines? and What are the main differences between granule and powder packaging systems? As a professional Chinese packaging equipment manufacturer with extensive global experience, Yuheng Technology Co., Ltd provides this comprehensive guide to help international buyers understand these essential packaging solutions.

The price of granule packaging machines varies significantly depending on their automation level and production capacity. Entry-level semi-automatic models from Yuheng Technology typically range between $18,000 and $35,000, offering reliable performance for small to medium businesses packaging products like rice, seeds, nuts or plastic pellets. These machines feature gravity-fed weighing systems and straightforward operation suitable for various free-flowing granular materials. More advanced automatic systems priced from $40,000 to $85,000 incorporate multi-head weighers and touchscreen controls, delivering higher precision and output for medium-sized food processing plants. For large-scale agricultural or industrial producers requiring maximum efficiency, high-speed production lines with robotic integration and vision inspection capabilities can reach $90,000 to $200,000 or more, handling up to 400 bags per minute with exceptional accuracy.

Understanding the differences between granule and powder packaging machines is crucial for selecting the right equipment. The most fundamental distinction lies in the materials they handle. Granule packaging machines are specifically designed for solid, free-flowing particles like agricultural products (beans, grains), industrial materials (plastic pellets, fertilizers) and food items (nuts, candy). These materials typically have consistent particle sizes and good flow characteristics. Powder packaging systems, on the other hand, are engineered for fine, often cohesive materials including food ingredients (flour, spices), pharmaceuticals (powdered medicines) and chemicals (detergents, pigments). The different material properties require distinct handling approaches throughout the packaging process.

The feeding mechanisms represent another key difference between these two types of packaging machines. Granule packers primarily use gravity and vibration-based feeding systems that take advantage of the material’s natural flowability. These systems often incorporate anti-bridging agitators to prevent material clumping and ensure consistent flow to the weighing stations. Powder packaging machines typically employ twin-screw feeding mechanisms that gently move the material while preventing compaction. Many powder systems also include deaeration systems to remove trapped air from light, fluffy materials before packaging. The different feeding approaches result in slightly varying accuracy levels, with granule packers typically achieving ±0.3-0.5% and powder systems reaching ±0.5-1% weighing precision.

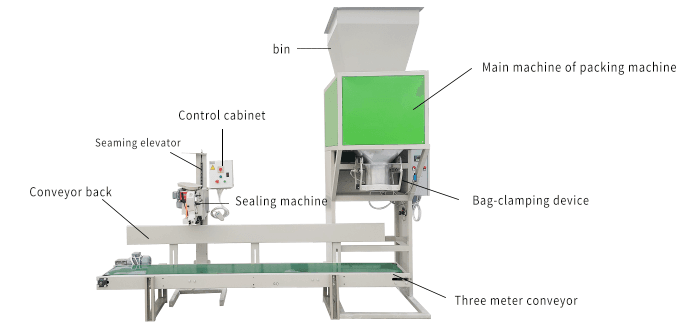

Structural components also differ significantly between these packaging solutions. Granule packaging machines usually feature vibratory feed hoppers, multi-head weighing systems and mechanical bagging stations designed to handle the impact and abrasion of solid particles. They often include dust collection ports to manage any fine particles that may separate during handling. Powder packaging systems require more specialized components like sealed screw feeders, anti-static coatings and dedicated dust recovery systems to contain the fine materials. Many powder machines also incorporate precision aeration controls to regulate material flow characteristics during packaging.

Operational considerations vary between the two machine types as well. Granule packaging systems require regular vibration adjustment to maintain optimal material flow, periodic weigher calibration to ensure measurement accuracy, and ongoing particle size monitoring to prevent processing issues. Powder packaging machines demand more frequent screw cleaning to prevent material buildup, careful moisture control to avoid clumping, and specialized dust management to maintain a clean working environment. Yuheng Technology understands that some materials exhibit characteristics of both granules and powders, which is why we offer hybrid machines capable of handling mixed-phase materials, convertible systems with interchangeable feed mechanisms, and universal platforms that allow for future upgrades as packaging needs evolve.

As an experienced Chinese manufacturer serving international markets, Yuheng Technology combines reliable engineering with cost-effective production methods to deliver high-quality packaging solutions. Our granule packaging machines feature heavy-duty stainless steel construction, ±0.3% weighing accuracy and come with a 5-year structural warranty for peace of mind. We offer various bag types including pouches, sacks and bulk bags to meet different packaging requirements, with power configurations adaptable to local standards (typically 380V/50Hz). All our equipment meets international CE and ISO standards, with FDA-compliant models available for food and pharmaceutical applications.

If you want to know more about the equipment configuration and other details, please feel free to communicate with us