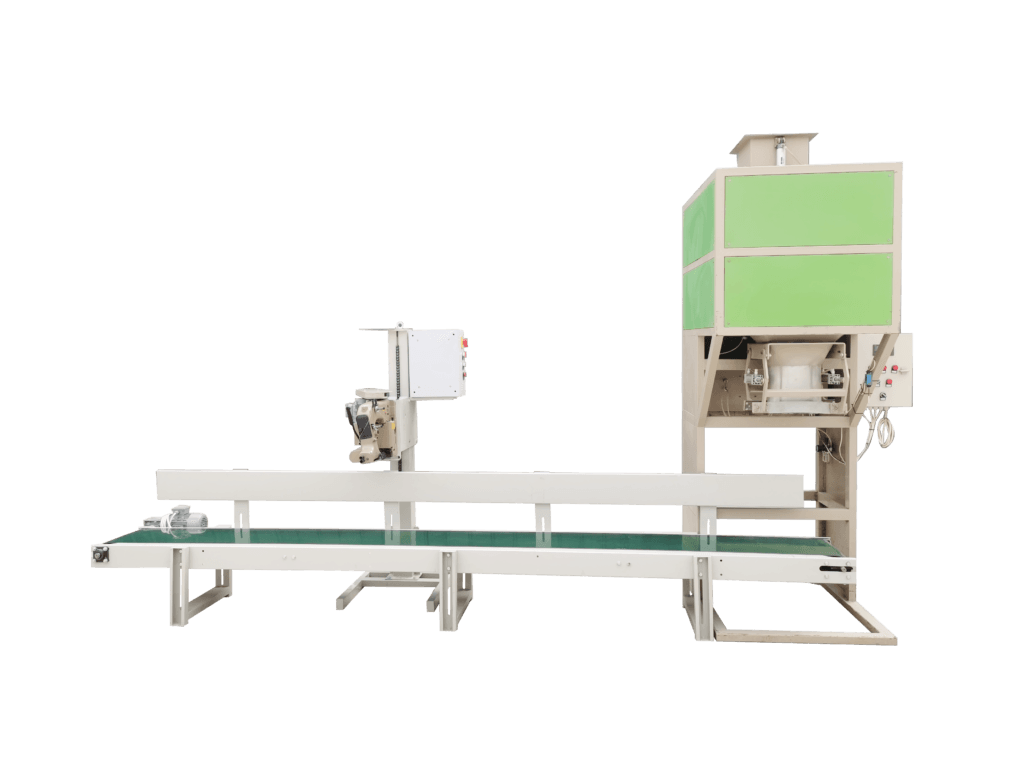

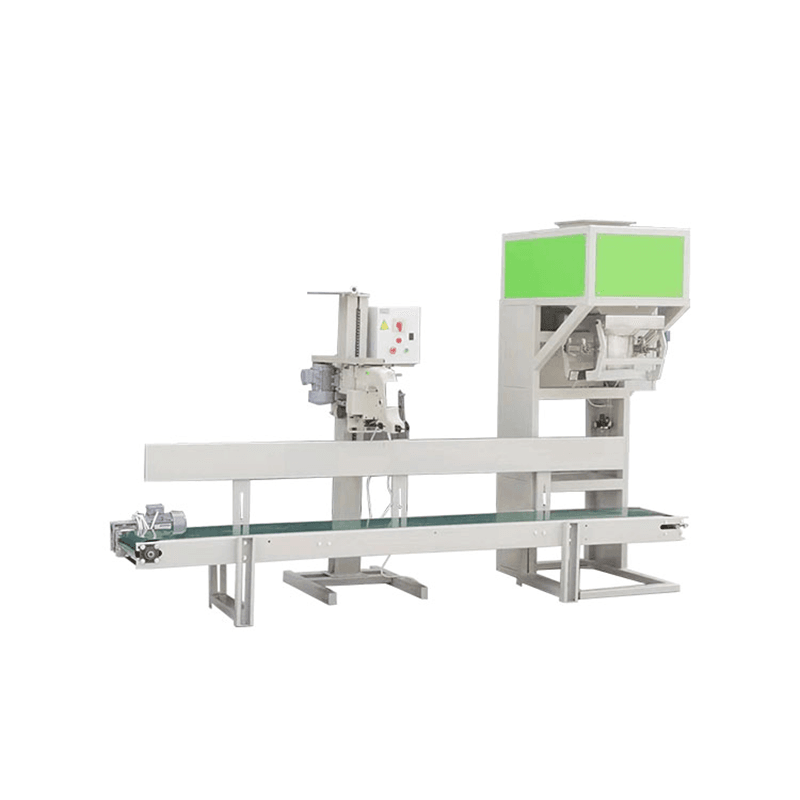

How Much Does the Xiaomi Packaging Machine Cost? And How to Maintain It?

The cost of a xiaomi packaging machine is influenced not only by its design and components but also by the methods used during operation. Proper usage and maintenance are key factors that can significantly extend the service life of the packaging machine. In this article, we will explain how proper maintenance practices ensure optimal performance and longevity, and outline the various levels of care required.

Factors Affecting the Price

The price of a packaging machine such as the xiaomi packaging machine depends on:

- Design & Components: High-quality parts and innovative design contribute to higher costs.

- Usage Method: Correct operating procedures can extend the lifespan of the machine, reducing long-term expenses.

- Automation & Technology: Advanced digital control and monitoring features also play a role in pricing.

In some cases, similar technologies are applied in a pellet packaging machine, where precision and efficiency in packaging fine particulate products are essential.

Maintenance: The Key to Longevity

The service life of the xiaomi packaging machine is closely tied to regular and proper maintenance. Routine care is vital both during and after operation. The maintenance strategy is divided into several levels to ensure that every component is in optimal condition.

Routine Maintenance

Routine maintenance focuses on cleaning, smoothing surfaces, inspection, and tightening of all relevant parts. It should be carried out both during machine operation and after each production cycle. This ensures that the machine continues to run efficiently and prevents the buildup of contaminants that could affect performance.

Level 1 Maintenance

Building upon routine care, Level 1 Maintenance involves:

- Cleaning and Smoothing: Ensuring all surfaces and components are free from debris.

- Tightening and Inspection: Checking all parts for secure fastening and proper alignment. This stage is crucial for the early detection of any minor issues before they develop into significant problems.

Level 2 Maintenance

Level 2 Maintenance emphasizes detailed inspection and adjustment. This includes:

- Inspection and Adjustment: Focusing on the engine, clutch, transmission, drive components, steering, and braking mechanisms. By carefully monitoring these critical parts, operators can maintain the optimal performance of the xiaomi packaging machine and other types of packaging machines.

Level 3 Maintenance

Level 3 Maintenance is more comprehensive and involves:

- Testing and Adjustment: Systematic checks and fine-tuning of all components.

- Fault Elimination: Identifying and removing potential hidden faults.

- Balancing Wear: Ensuring that all parts experience even wear to prevent premature failure. This level includes diagnostic tests for components that show early signs of malfunction, followed by necessary replacements or adjustments.

Seasonal Maintenance

Seasonal maintenance is essential before major weather changes, such as the onset of summer or winter. For the xiaomi packaging machine, this includes:

- Power System Checks: Inspecting and servicing the engine.

- Conveyor System Maintenance: Examining spiral shafts and belt conveyors.

- Air Compression System: Cleaning and sealing the air compressor.

- Control System Inspection: Servicing the electromechanical control cabinet (ideally under guidance from authorized service engineers). This proactive maintenance helps ensure the machine is ready to handle seasonal stresses.

Idle Maintenance

When the xiaomi packaging machine is not in use—such as during seasonal shutdowns or holidays—proper idle maintenance is crucial. This involves:

- Cleaning and Tidying: Thoroughly cleaning the machine to remove dust and debris.

- Moisture and Corrosion Prevention: Protecting sensitive components against moisture and corrosion.

- Proper Storage: Ensuring all parts are stored safely to avoid damage. These steps help preserve the machine’s condition during periods of inactivity, ensuring a smooth restart when production resumes.

By following these detailed maintenance procedures, operators can significantly extend the lifespan of a xiaomi packaging machine and optimize the performance of any packaging machine or pellet packaging machine in their production line. Regular cleaning, timely adjustments, and comprehensive seasonal checks are all essential to keep the machine running at peak efficiency, ultimately reducing long-term costs and ensuring reliable operation.

How much does a packaging machine cost?

Price is a matter that users are concerned about. Generally speaking, the cost of purchasing a packaging machine ranges from 3000-80000usd. Due to the differences in model specifications and production technical parameters, it is difficult to give users a definite price figure.

How much does a packaging machine cost? It is more in line with the development demands of the modern market. For more detailed information such as equipment configuration and on-site trial operation, please feel free to come to our factory for a visit at any time.