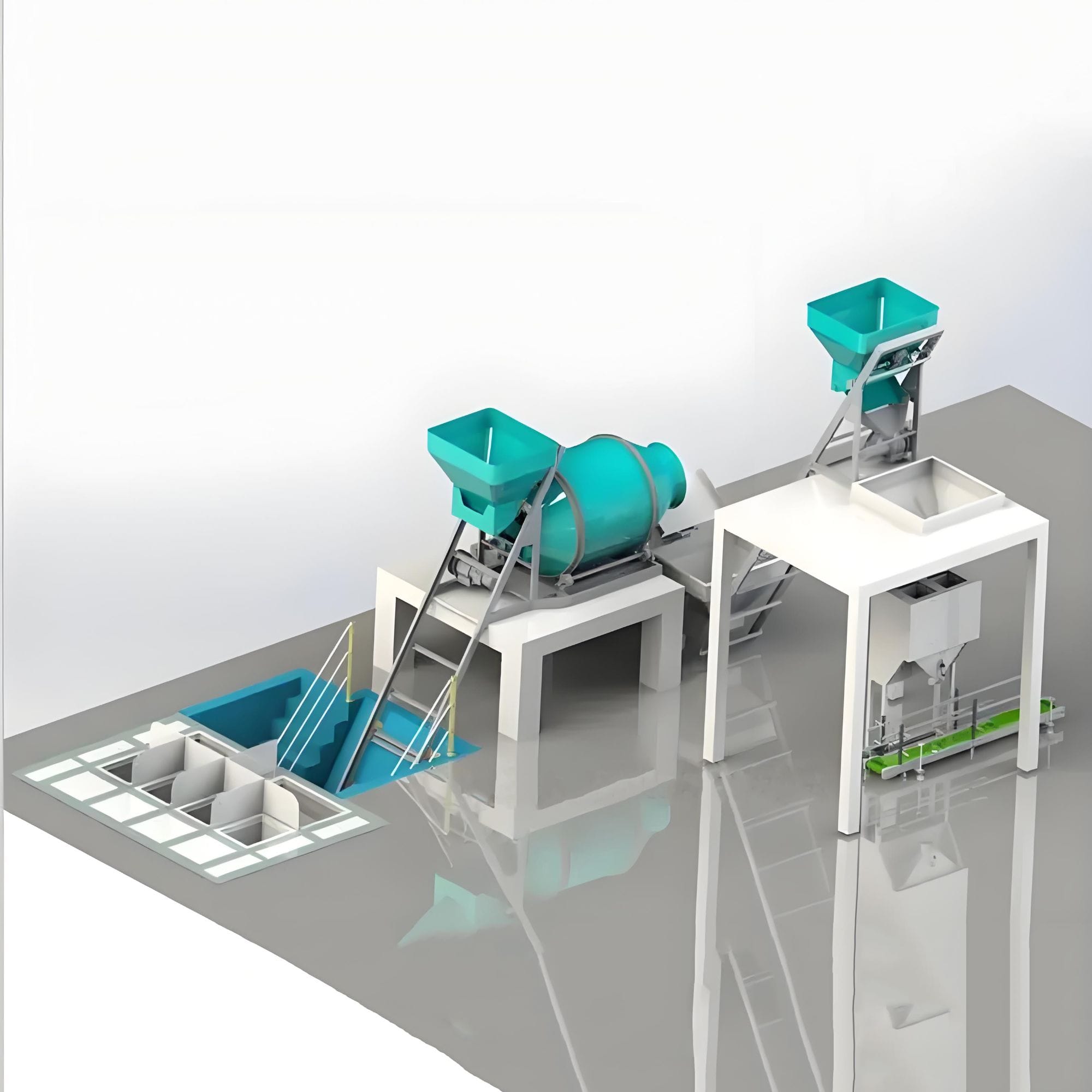

Cost of Complete Packaging Machinery Systems & 3 Key Strategies for Cost Control

The price range for complete packaging machinery systems varies significantly based on configuration, typically falling between $50,000 to $500,000+. To maximize ROI, manufacturers should implement these three fundamental cost-control strategies:

1. Strategic Equipment Selection

- Prioritize integrated systems with unified controls to minimize compatibility issues

- Opt for modular designs that allow future upgrades

- Verify energy efficiency certifications (e.g., IE3/IE4 motors)

- Demand 12-18 month warranty coverage on critical components

2. Precision Installation & Layout

- Implement U-shaped production lines to reduce floor space by 20-30%

- Ensure ERGONOMIC WORKSTATION DESIGN (maintain 60-80cm operational zones)

- Install noise dampening enclosures (target <75dB)

- Integrate centralized dust collection with HEPA filtration

3. Smart Production Optimization

| Focus Area | Cost-Saving Solution |

|---|---|

| Energy Use | Install servo motors (30-50% less power than conventional) |

| Maintenance | Implement IoT-enabled predictive maintenance systems |

| Labor | Automate 80%+ of material handling with robotic arms |

| Materials | Use AI-based film optimization software (reduces waste by 15-25%) |

Proven Results: Manufacturers applying these methods typically achieve:

- 18-22% reduction in per-unit packaging costs

- 30-40% decrease in unplanned downtime

- 12-15 month payback period for automation investments

Critical Reminder: Always conduct Total Cost of Ownership (TCO) analysis before purchase, factoring in:

- Energy consumption per 1,000 units

- Expected maintenance costs over 5 years

- Retrofitting/expansion capabilities

If you want to know more about the equipment configuration and other details, please feel free to communicate with us