How Much Does a Granule Packaging Machine Cost? How to Solve Air Leakage During Packaging?

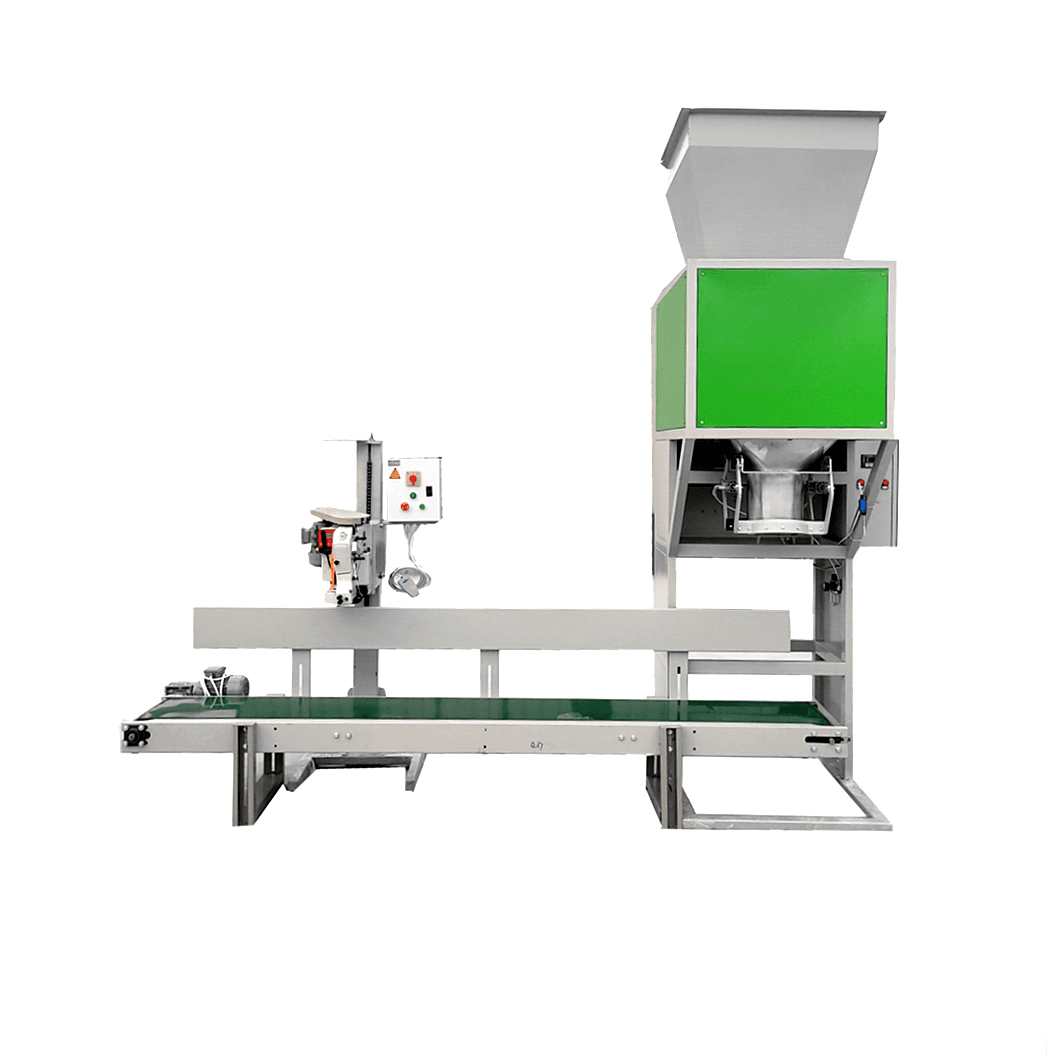

The granule packaging machine is a vital piece of equipment in modern industrial automation, widely used for its user-friendly operation, stable performance, and long service life. It enables efficient and orderly automated packaging processes. But what should you do when encountering air leakage during operation? Let’s explore the price range and solutions.

Granule Packaging Machine Price Range

The cost of a granule packaging machine varies based on its specifications and features:

- Basic models: $5,000–$15,000

- High-speed, fully automated systems: $20,000–$60,000+

Key factors affecting price:

✔ Packaging speed (bags per minute)

✔ Multi-head weigher precision

✔ Material (stainless steel for food/pharma industries)

✔ Additional functions (e.g., gas flushing for extended shelf life)

How to Fix Air Leakage During Packaging

Air leaks can compromise product freshness and packaging quality. Here’s a step-by-step troubleshooting guide:

1. Inspect the Tubing

- Issue: Aging or corroded tubes may crack, causing leaks.

- Solution: Replace damaged tubing immediately with compatible materials.

2. Check Sealing Integrity

- Issue: Loose or misaligned seals lead to poor airtightness.

- Solution: Adjust or replace the sealing components to ensure a tight fit.

3. Examine Seals & Gaskets

- Issue: Worn-out seals fail to maintain vacuum pressure.

- Solution: Replace damaged seals with OEM parts for optimal performance.

4. Test the Solenoid Valve

- Issue: Faulty valves may leak air intermittently.

- Solution: Repair or replace the solenoid valve if it fails to hold pressure.

5. Inspect the Vacuum Pump

- Issue: A malfunctioning pump reduces suction efficiency.

- Solution: Service the pump regularly or replace it if irreparable.

6. Monitor the Vacuum Gauge

- Issue: A defective gauge may give false readings.

- Solution: Replace the gauge if it shows inconsistencies.

7. Assess the Airbag (If Applicable)

- Issue: Tears in the airbag can cause pressure loss.

- Solution: Replace the airbag if damaged.

Preventive Maintenance Tips

✅ Regularly clean the machine to prevent debris buildup.

✅ Lubricate moving parts to reduce wear and tear.

✅ Schedule professional servicing annually to detect hidden issues.

How much does a granular packaging machine cost?

Regarding the price of the granular packaging machine, it varies slightly depending on the market situation. There are many sellers in the market, including those who sell directly from the manufacturer, those who act as middlemen, and those who sell second-hand ones. Even for the same model, if manufactured by different manufacturers, there will be slight differences in parameters such as output and motor power. Therefore, when selling the same type of equipment, the prices may also vary slightly.

How much does a granular packaging machine cost? What should be done if there is air leakage during the packaging process? If you want to know more detailed information about equipment configuration, on-site trial operation and other details, please feel free to come to our factory for on-site inspection at any time.