Description

Introduction of Organic Fertilizer Production Line

Organic fertilizer is use chickens, pigs, cattle, horse, sheep, other livestock and poultry manure, also crop straw as raw materials, adopt bio-fermentation technology, scientific processing (fermentation, drying, crushing, mixing, granulating, cooling, etc.) to produce high quality and stable long green fertilizer efficiency and environmental protection and efficient organic fertilizer.

What are the raw materials for organic fertilizer?

Animal manure: chicken manure, pig manure, cow manure, earthworm manureCrop residues: corn stover, wheat straw, straw, leaves, weeds, peanut seedlings, soybean stalks, palm fiber, oil cake: peanut cake, soybean cake, cottonseed cake, rapeseed cake

Industrial waste: wine dregs, vinegar dregs, cassava dregs, sugar dregs, furfural dregsKitchen waste

Composting materials: kitchen waste, plant residues, lawn clippings, straw, wood chips and other organic waste, etc.

Seaweed and aquatic plants: rice seedlings, lotus seedlings, etc.

Food processing waste: fruit peels, fruit pomace, coffee grounds, etc.

Fish meal and fish bone meal

Humus soil

Municipal sludge

Humic acid: potassium humate, xanthate

If you have a better idea, or would like to do an experimental test as well, please contact us right away!

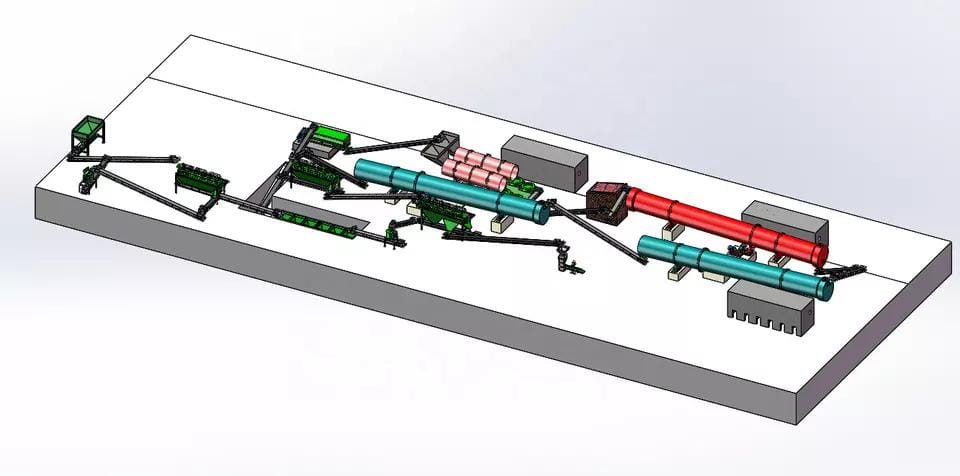

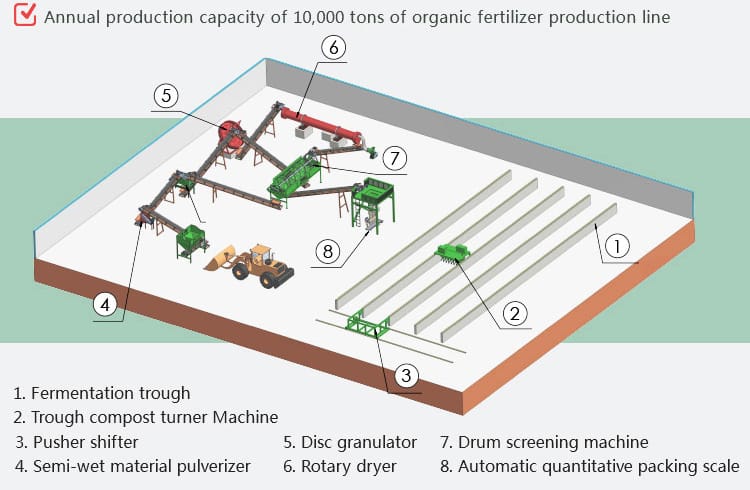

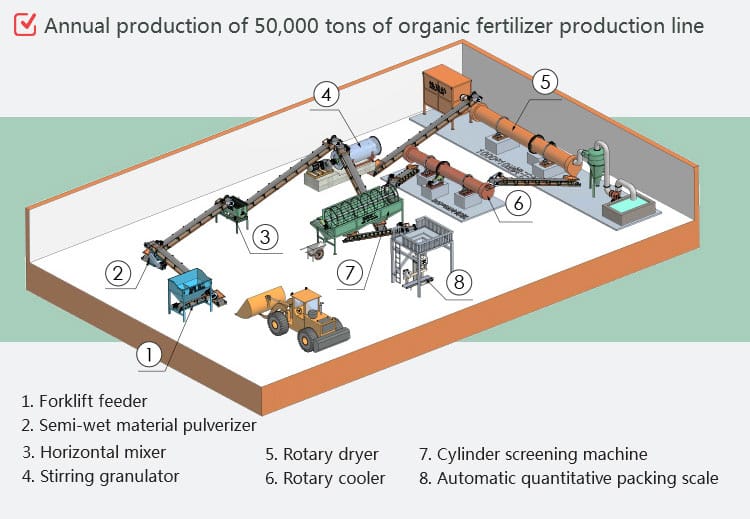

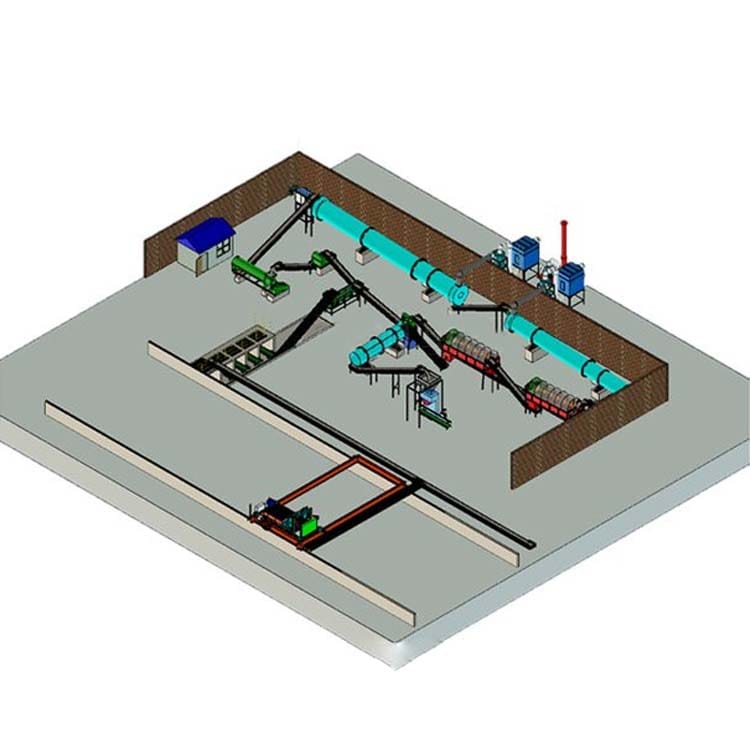

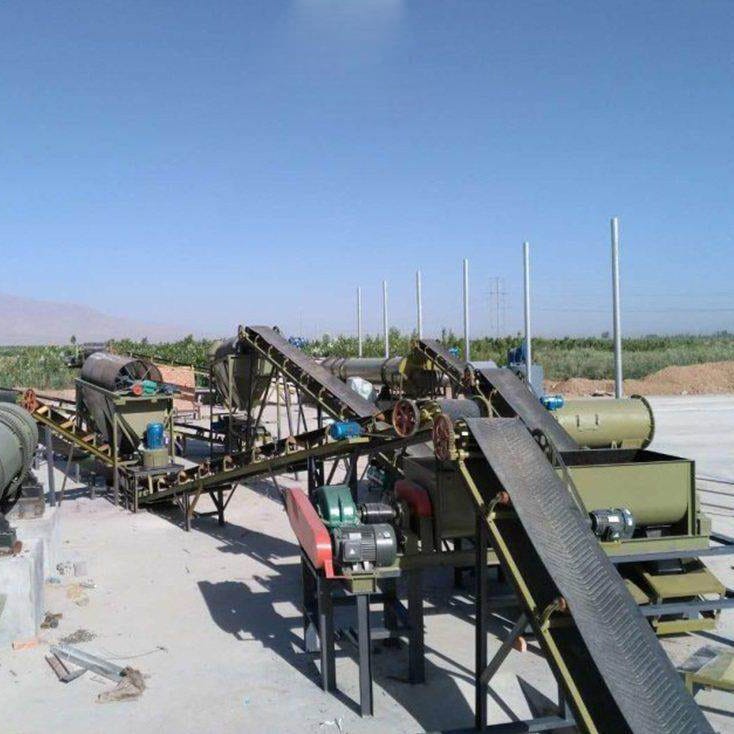

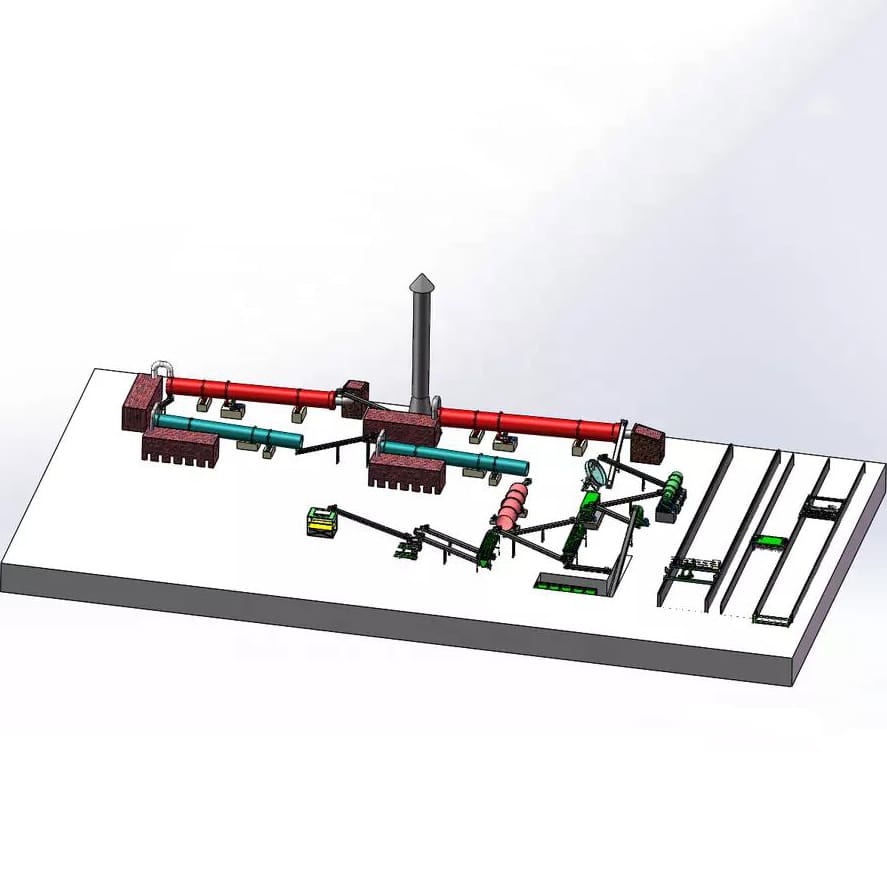

Structure of Organic Fertilizer Production Line

Working principle

The process of organic fertilizer production line is as follows:

1.Raw material fermentation—2 Automatic belt scale batching system — 3 Crushing, mixing — 4 Disc granulation, drum granulation, extrusion granulation — 5 Dryer, Drying Organic Fertilizer Granules—6 Cooling Machine, Cooling Organic Fertilizer Particles— 7 Screening Machine. Screening Out Qualified Organic Fertilizer Particles — 8 Coating Membrane machine, coated film granules, making the granules smoother—-9 Packing scale, automatic filling organic fertilizer granules–10 seal

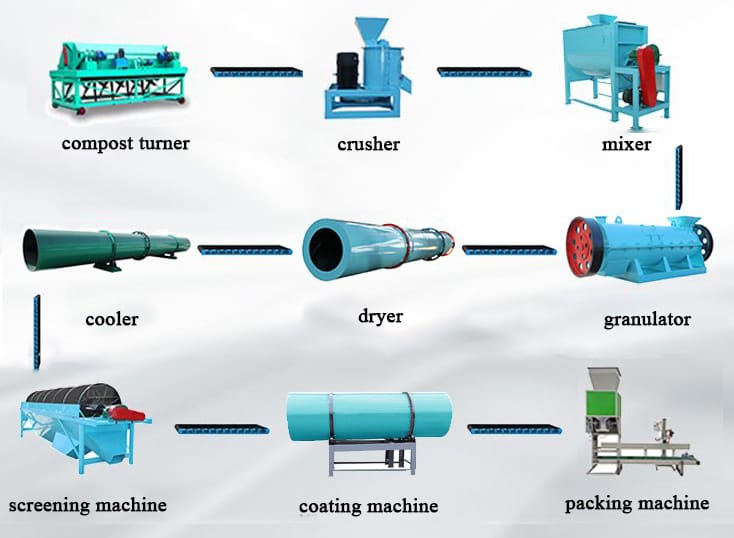

Supporting Equipment of Organic Fertilizer Production Line

Fermentation equipment: Mainly used for the fermentation of raw materials, to achieve industrial production, no dead ends.

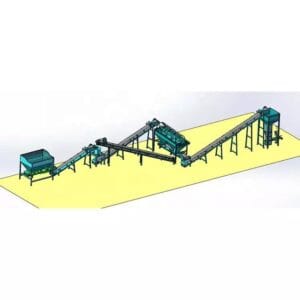

Crushing machine: Mainly used for the crushing of raw materials to meet the requirements of granulation.

Mixing machine: It is used for mixing and stirring materials, adjusting the moisture content of materials, adding trace elements to meet the needs of granulation.

Organic granulator: The cutter head is movable and adjustable, which is conducive to granulation, and is made of wear-resistant alloy. Mainly used for granulation of various powdery materials.

Throw round shaping machine: The machine is mainly used in conjunction with the granulator to increase the granulation output and achieve smooth and bright appearance of the granules.

Rotary dryer machine: It is mainly used for drying after granulation, so that the granules can quickly reduce the moisture at high temperature, which is convenient for storage and achieves continuous and uninterrupted production.

Cooling machine: It is mainly used to cool down and remove moisture after drying, so that the material can quickly reach normal temperature, meet the storage requirements, and realize continuous and uninterrupted production.

Screener machine: Wear-resistant steel mesh. It is mainly used for the separation of finished products and returned materials, and can also realize the classification of finished products, so that the finished products can be evenly classified.

Coating machine: It is mainly used for dusting powder or liquid coating of granules, which can prevent caking and improve brightness. It is also used in various multi-functional bacterial fertilizers.

Package machine: It is mainly composed of main machine, machine column, sewing machine head and conveyor belt. Different specifications can be packaged to improve work efficiency and reduce operating costs.

Feature of Organic Fertilizer Production Line

Biological organic fertilizer project is featured with Short-period construction, high investment repayment rate, low risk and short payback period. Organic fertilizer production technology use the newest special equipment and technology to process all kinds of organic wastes – farm’s livestock manure, the organic wastes of plants, agricultural wastes, sludge, residual leftovers, the sugar mill wastes into the green and protecting environmental fertilizer( bio-organic fertilizer).

Reviews

There are no reviews yet.